You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speedo not working hard shifting & abs light on HELP

- Thread starter 8vettes

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Yo 217,

Try a Self Test for Diagnostic Trouble Codes (DTC)s by my pal, BroncoJoe19 @ Code Reader

H1 CHECK SPEEDOMETER OPERATION

Is speedometer free from hesitation or sticking when accelerating or decelerating smoothly? This may be confirmed by performing the following test:

Press and hold the RESET button on the front of the speedometer while turning the key to RUN.

Release the RESET button.

Does the pointer smoothly prove out, or sweep from 0 to maximum speed then back to 0?

Yes GO to H2 .

No After verifying good power and ground connections, GO to G6 . REPLACE instrument cluster . VERIFY proper operation.

H2 CHECK ODOMETER DISPLAY

The trip odometer must be currently displayed for the RESET button to work.

If unsure about missing or extra segments, perform the odometer display self test as follows:

Press and hold the reset button on the front of the speedometer while turning the key to RUN.

Release the RESET button.

Press and release the select button. The odometer will begin with all zeroes and step through the display test each time the select button is pushed. Refer to PSOM Display Test Sequence below for exact display.

The first digit on the left does not always match the other digits.

Key off to exit this test.

Are all odometer digits formed correctly (no extra or missing segments)? Do the select and reset buttons work normally?

Yes GO to H3 .

No REPLACE instrument cluster . VERIFY proper operation.

H3 CHECK SPEEDOMETER POINTER

Does pointer jump or waver at a constant speed?

Yes GO to H4 .

No GO to H5 .

H4 CHECK RABS SPEED SENSOR RING AND SENSOR

Check for presence of the following conditions.

Damaged, missing or bent teeth

Metal chips on speed sensor

Open or shorted sensor

Improper gap between sensor and speed sensor ring

Refer to Section 06-09A for additional information.

Are any of the above conditions present?

Yes REPAIR or REPLACE as necessary. VERIFY proper operation.

No REPLACE the instrument cluster . VERIFY proper operation.

H5 CHECK FOR STUCK POINTER

Is pointer stuck at upper pointer stop?

Yes GO to H6.

No Speedometer normal.

H6 SPEEDOMETER POINTER PROVEOUT

Press and hold the RESET button on the front of the speedometer while turning the key to RUN.

Release the RESET button. The pointer would normally prove out, or sweep from the lower to upper pointer stop and back again. In this case, the pointer will "jump back" to where it should be in the sweep and continue to sweep normally when the pointer gets to within 180 degrees of the upper pointer stop (about 56 km/h [35 mph]).

Key off.

Does the pointer return to the normal position?

Yes Speedometer normal.

No REPLACE the instrument cluster . VERIFY proper operation.

PINPOINT TEST J: SPEED CONTROL, PCM OR ELECTRONIC TRANSMISSION DISPLAY INOPERATIVE OR ERRATIC

NOTE: Follow this procedure only after being referred here from Section 10-03, Powertrain Control/Emissions Diagnosis Manual, or electronic transmission shop manual diagnostics.

J1 CHECK ANTI-LOCK LAMP ILLUMINATION

Key to RUN.

Does anti-lock lamp on dash go out after self-test?

Yes GO to J2 .

No REFER to Section 06-09A or Section 06-09B .

J2 CHECK SPEEDOMETER SPEED OUTPUT SIGNAL

To determine if there is a short between the PSOM and the speed control module, the vehicle speed control may be used as a good indicator. If it works normally above 56 km/h (35 mph), this means that the speedometer module is at least receiving a speed input signal and the wiring and sensor can be assumed to be good. CAUTION: Before checking the continuity of any circuit, make sure there is no voltage present in the circuit prior to switching the test equipment to the resistance function to avoid damage to equipment. Refer to the test equipment user's manual for additional information. NOTE: Only wiring harness end of connector is to be probed.

Use ohmmeter to check for opens in wiring between Pin 7 (speed out) and the affected module. Verify that the terminals in PSOM wiring connector are completely seated in the connector.

Is the circuit open?

Yes SERVICE wiring between speedometer and affected module as required.

No VERIFY proper operation. GO to J3 .

J3 CHECK SPEED INPUT SIGNAL

Connect Rotunda 88 Digital Multimeter 105-00053 or equivalent to Pin 4 (speed ) and Pin 5 (speed -). If available, a frequency counter may be connected to Pin 4 (speed in ) and Pin 5 (speed in -). CAUTION: Make sure multimeter is in the voltage function and not in the resistance function to avoid damage to multimeter. NOTE: Only wiring harness end of connector is to be probed.

Does the displayed frequency of the signal increase smoothly and continuously from 0 to approximately 667 Hz at approximately 48 km/h (30 mph)? OR does the voltage increase smoothly and continuously from 0 to approximately 3.5 volts as vehicle speed increases from 0 to approximately 48 km/h (30 mph)?

Yes REPLACE instrument cluster . SERVICE wiring.

No CHECK for open wiring. If no problems are found, REFER to Section 06-09A or Section 06-09B .

B1 CHECK THAT CONDITION OCCURS ONLY WHILE USING SPEED CONTROL

Drive vehicle at the speed in which the condition occurs.

Does the speedometer needle waiver by more than � 2 mph?

Yes Bad Programmable Speedometer/Odometer Module, RABS speed sensor, or rear axle ring gear.

No SERVICE as necessary. GO to B2 .

B2 CHECK PROGRAMMABLE SPEEDOMETER/ODOMETER MODULE OUTPUT SIGNAL

Check PSOM output signal.

Did PSOM pass output signal test?

Yes GO to B3 .

No SERVICE as required.

B3 CHECK FOR BINDING IN SPEED CONTROL ACTUATOR CABLE AND THROTTLE BODY LINKAGE

Check for binding or sticking of speed control cable or throttle linkage and throttle plate.

Make sure throttle cable bracket and speed control servo bracket are not loose.

Are components OK?

Yes REPLACE speed control servo and VERIFY condition is corrected.

No SERVICE as required.

Try a Self Test for Diagnostic Trouble Codes (DTC)s by my pal, BroncoJoe19 @ Code Reader

H1 CHECK SPEEDOMETER OPERATION

Is speedometer free from hesitation or sticking when accelerating or decelerating smoothly? This may be confirmed by performing the following test:

Press and hold the RESET button on the front of the speedometer while turning the key to RUN.

Release the RESET button.

Does the pointer smoothly prove out, or sweep from 0 to maximum speed then back to 0?

Yes GO to H2 .

No After verifying good power and ground connections, GO to G6 . REPLACE instrument cluster . VERIFY proper operation.

H2 CHECK ODOMETER DISPLAY

The trip odometer must be currently displayed for the RESET button to work.

If unsure about missing or extra segments, perform the odometer display self test as follows:

Press and hold the reset button on the front of the speedometer while turning the key to RUN.

Release the RESET button.

Press and release the select button. The odometer will begin with all zeroes and step through the display test each time the select button is pushed. Refer to PSOM Display Test Sequence below for exact display.

The first digit on the left does not always match the other digits.

Key off to exit this test.

Are all odometer digits formed correctly (no extra or missing segments)? Do the select and reset buttons work normally?

Yes GO to H3 .

No REPLACE instrument cluster . VERIFY proper operation.

H3 CHECK SPEEDOMETER POINTER

Does pointer jump or waver at a constant speed?

Yes GO to H4 .

No GO to H5 .

H4 CHECK RABS SPEED SENSOR RING AND SENSOR

Check for presence of the following conditions.

Damaged, missing or bent teeth

Metal chips on speed sensor

Open or shorted sensor

Improper gap between sensor and speed sensor ring

Refer to Section 06-09A for additional information.

Are any of the above conditions present?

Yes REPAIR or REPLACE as necessary. VERIFY proper operation.

No REPLACE the instrument cluster . VERIFY proper operation.

H5 CHECK FOR STUCK POINTER

Is pointer stuck at upper pointer stop?

Yes GO to H6.

No Speedometer normal.

H6 SPEEDOMETER POINTER PROVEOUT

Press and hold the RESET button on the front of the speedometer while turning the key to RUN.

Release the RESET button. The pointer would normally prove out, or sweep from the lower to upper pointer stop and back again. In this case, the pointer will "jump back" to where it should be in the sweep and continue to sweep normally when the pointer gets to within 180 degrees of the upper pointer stop (about 56 km/h [35 mph]).

Key off.

Does the pointer return to the normal position?

Yes Speedometer normal.

No REPLACE the instrument cluster . VERIFY proper operation.

PINPOINT TEST J: SPEED CONTROL, PCM OR ELECTRONIC TRANSMISSION DISPLAY INOPERATIVE OR ERRATIC

NOTE: Follow this procedure only after being referred here from Section 10-03, Powertrain Control/Emissions Diagnosis Manual, or electronic transmission shop manual diagnostics.

J1 CHECK ANTI-LOCK LAMP ILLUMINATION

Key to RUN.

Does anti-lock lamp on dash go out after self-test?

Yes GO to J2 .

No REFER to Section 06-09A or Section 06-09B .

J2 CHECK SPEEDOMETER SPEED OUTPUT SIGNAL

To determine if there is a short between the PSOM and the speed control module, the vehicle speed control may be used as a good indicator. If it works normally above 56 km/h (35 mph), this means that the speedometer module is at least receiving a speed input signal and the wiring and sensor can be assumed to be good. CAUTION: Before checking the continuity of any circuit, make sure there is no voltage present in the circuit prior to switching the test equipment to the resistance function to avoid damage to equipment. Refer to the test equipment user's manual for additional information. NOTE: Only wiring harness end of connector is to be probed.

Use ohmmeter to check for opens in wiring between Pin 7 (speed out) and the affected module. Verify that the terminals in PSOM wiring connector are completely seated in the connector.

Is the circuit open?

Yes SERVICE wiring between speedometer and affected module as required.

No VERIFY proper operation. GO to J3 .

J3 CHECK SPEED INPUT SIGNAL

Connect Rotunda 88 Digital Multimeter 105-00053 or equivalent to Pin 4 (speed ) and Pin 5 (speed -). If available, a frequency counter may be connected to Pin 4 (speed in ) and Pin 5 (speed in -). CAUTION: Make sure multimeter is in the voltage function and not in the resistance function to avoid damage to multimeter. NOTE: Only wiring harness end of connector is to be probed.

Does the displayed frequency of the signal increase smoothly and continuously from 0 to approximately 667 Hz at approximately 48 km/h (30 mph)? OR does the voltage increase smoothly and continuously from 0 to approximately 3.5 volts as vehicle speed increases from 0 to approximately 48 km/h (30 mph)?

Yes REPLACE instrument cluster . SERVICE wiring.

No CHECK for open wiring. If no problems are found, REFER to Section 06-09A or Section 06-09B .

B1 CHECK THAT CONDITION OCCURS ONLY WHILE USING SPEED CONTROL

Drive vehicle at the speed in which the condition occurs.

Does the speedometer needle waiver by more than � 2 mph?

Yes Bad Programmable Speedometer/Odometer Module, RABS speed sensor, or rear axle ring gear.

No SERVICE as necessary. GO to B2 .

B2 CHECK PROGRAMMABLE SPEEDOMETER/ODOMETER MODULE OUTPUT SIGNAL

Check PSOM output signal.

Did PSOM pass output signal test?

Yes GO to B3 .

No SERVICE as required.

B3 CHECK FOR BINDING IN SPEED CONTROL ACTUATOR CABLE AND THROTTLE BODY LINKAGE

Check for binding or sticking of speed control cable or throttle linkage and throttle plate.

Make sure throttle cable bracket and speed control servo bracket are not loose.

Are components OK?

Yes REPLACE speed control servo and VERIFY condition is corrected.

No SERVICE as required.

Great!

I have a huge lag by my internet provider!!!!

☢☢☢

☢☢☢

I have a huge lag by my internet provider!!!!

Interceptor Bronco

New member

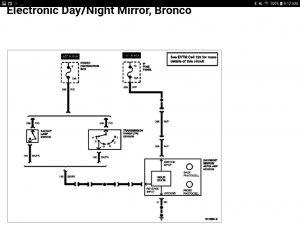

How did you repair?Fixed it...Mine was the black/pink wire in the auto dimming rear view mirror. Huge thanks to this forum, you saved me a ton of time and effort. Works like a charm now!

How did you repair?

Electrical tape over the cracked wire insulation.

hi all its been awhile since ive been here

well a year and new hip later im starting to be able to work on my 94 again . thanks to Miesk5 i was able to get my old girl back on the road with the abs module wire jump but now would like to get it fixed proper with abs system working again . tries contacting bba reman and they seem to out of business anyone have another source for a rebuild ? thanks and happy new year to all

well a year and new hip later im starting to be able to work on my 94 again . thanks to Miesk5 i was able to get my old girl back on the road with the abs module wire jump but now would like to get it fixed proper with abs system working again . tries contacting bba reman and they seem to out of business anyone have another source for a rebuild ? thanks and happy new year to all

Similar threads

- Replies

- 16

- Views

- 1K

- Replies

- 0

- Views

- 170