I have been restoring my 1970 Bronco since July 2003. This is a complete frame off restoration. This bronco has been passed down from my older brother to my middle brother and then I bought it in 1996. It was my daily driver for 3 years and I bought a truck. I decide that it needed a frame off restoration. I have done almost all the work myself, except for lifting off the body (I need some help with that) and the custom exhaust (local shop).

Here is a list of all the things I have done:

Replaced all rusty panels

Media blasted tub, fenders, hood, doors, etc.

Media blasted frame and axles.

Rebuilt Engine, NP435 Transmission, Dana 20 Transfer case

Installed James Duff Long Radius Arms.

James Duff 3.5 inch front spring

Jeff Bronco 3.5 inch rear spring

Jeff Bronco Super Flex front Shock Hoops.

23 gallon gas tank

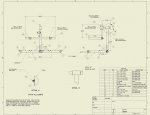

Custom made InBoard shock hoop on rear.

Dual 2 1/4 exhaust with Magnaflow Mufflers

Custom Hydraulic Clutch Setup

Centerforce Clutch

Beard Sportster HB front Seats

Beard Sportster bench seat in rear.

Gusseted and braced rear axle

All new stainless steel brake lines.

Jeff Bronco Headers

Body - Engine Compartment, underneath and inside tube Hippo-Lined with Denim Blue Metillac color.

plenty more

I am currently working on the body in preparation for paint. I am looking to have it done the First of July. The outside will be painted Denim Blue Metallic. I will post more picture as the things get done. Hopefully someone can get some ideas from my project and if you would like some more information just e-mail me.

Here is a list of all the things I have done:

Replaced all rusty panels

Media blasted tub, fenders, hood, doors, etc.

Media blasted frame and axles.

Rebuilt Engine, NP435 Transmission, Dana 20 Transfer case

Installed James Duff Long Radius Arms.

James Duff 3.5 inch front spring

Jeff Bronco 3.5 inch rear spring

Jeff Bronco Super Flex front Shock Hoops.

23 gallon gas tank

Custom made InBoard shock hoop on rear.

Dual 2 1/4 exhaust with Magnaflow Mufflers

Custom Hydraulic Clutch Setup

Centerforce Clutch

Beard Sportster HB front Seats

Beard Sportster bench seat in rear.

Gusseted and braced rear axle

All new stainless steel brake lines.

Jeff Bronco Headers

Body - Engine Compartment, underneath and inside tube Hippo-Lined with Denim Blue Metillac color.

plenty more

I am currently working on the body in preparation for paint. I am looking to have it done the First of July. The outside will be painted Denim Blue Metallic. I will post more picture as the things get done. Hopefully someone can get some ideas from my project and if you would like some more information just e-mail me.