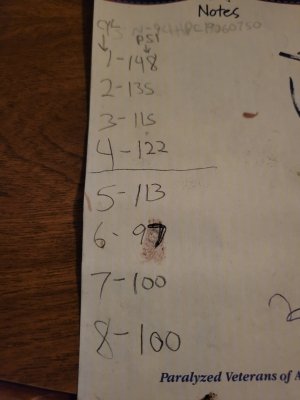

The results of a compression test a couple weeks ago.

The insides of the rubber tubes that go from the the airbox to the Tb were powder-dust coated, just like the insides of pretty much everything else ive gone into. Way to wipe out a set of rings- run it w/o a air filter!

The remedy- salvage '97 roller engine.

Will be going a ways into the roller to make sure all is in good shape before it gets swapped in.

If it's gonna get done- might as well do it right the 1st

I looked at your test results.

Yes, there

is a huge difference between cylinder readings.

My 2 cents.

First, did you check the valve clearances?

Engines with hydraulic lifters that sit for a long time often have collapsed lifters

that may or may not free up. If you've got some stuck lifters, the pressure readings will be wacky on the cylinders involved.

I've found that people do their engine compression testing in all sorts of ways, with the test cylinder being dry or wet, all plugs in- or only the one being tested, engine cold or warm (not hot), 1 revolution vs 4-10 (until the reading no longer climbs).

As a result, depending on method being used, the results can vary tremendously, or be less than the best guide to what is really going on.

I do my testing first dry on a cold engine, then if there is a significant difference between cylinders, wet (5ml or teaspoon of oil), followed by repeating it on a warm engine. At all times the throttle is blocked wide open, all spark plugs out, crank till the reading stops climbing-same number of revs each cylinder, And then do leakdown testing on all if any cylinder is low.

With a low reading cylinder from a DRY compression test, following up by doing a wet test will increase the rings ability to seal, and the pressure would come up considerably (during a 4-10 revolution test), but only for short time and then drop back down again to about what the dry reading was after say 30 revolutions.

(If the low reading is from a head gasket leak any cylinder pressure rise will be comparatively small.)

Just be sure to carefully measure the amount of oil added to each cylinder to ensure accurate results between cylinders.

ANY engine that's been sitting as long as you describe is liable to have had light (or not so light) cylinder rusting-which can degrade the ring sealing and result in low cylinder readings on one or more cylinders.

However,

its also a fair bet that one or both head gaskets may be leaking.

2 ADJACENT IDENTICAL LOW READING CYLINDERS is a classic sign of a head gasket leak between them.

Do you have access to equipment needed to do leak down testing-or a air fitting welded to a spark plug shell?

If so, before writing the engine off as a total loss, results of doing that might effect your thinking.

Air leaking into a water passage would show up as bubbles in the radiator.

Air leaking past an exhaust valve would be heard in the tail pipe.

Past an intake valve heard through the carb or throttle body.

Past the rings, it could be heard/felt coming out the valve cover breather or the dipstick tube.

If a leak is direct to the outside of the engine it can be heard or felt by running your hand around the cylinder head.

(If the gasket leak is direct to the valley between the heads it will be heard or felt through the valve cover breather or dipstick tube.)

If leakdown testing shows something OTHER than a serious ring leak, if it was me, I'd

at least pull the head on the right side cylinder bank-the one with all the low readings, before deciding to junk the engine and drop major bucks. Particularly if its a Cleveland.