Yo Smafugula,

Motor could be the Perpetrator.

Use a 12-18 VDC portable tool battery and Test motor at it's connector; Inspect motor connector for terminal corrosion & what Ford describes as terminal back-out, which can be caused by a loose terminal or a worn connector body, etc.

worn or damaged brushes, commutator, & windings ground through the motor's internal CB

"To test the electrical system, remove the access panel from inside the tailgate. Run test wires from the battery directly to the window motor connector (Yellow & red wires coming right out of the motor) to confirm that the motor works.

it should be positive to red, & negative to yellow. Be ready for the window to move, keep hands & wires clear. Make all the connections but 1, then connect & disconnect the last wire quickly to see if it tries to go the right way. If it tries to go the wrong way, reverse the wires (This also makes it so that you can lower the window & get the tailgate open to continue testing).

A- If it runs & the window moves when wired directly to the battery, perform the following tests: A.1- With both switches at rest & the latch switch closed, connect a tester between the positive test wire from the battery & each wire from the tailgate loom at the connector for the motor. Both should read 12v. If they do the ground is good.

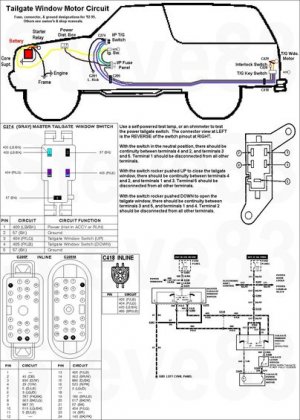

If they don't, refer to Seabronc's wiring diagram linked above to trace it down, or tell us what you find.

A.2- With the latch switch closed, connect the tester between the negative test wire from the battery & each wire from the loom at the connector for the motor. The red wire should read 12v when either switch is in the down position, the yellow wire should read 12v when either switch is in the up position. If they don't, refer to Seabronc's's wiring diagram linked above to trace it down, or tell us what you find.

A.3- If everything tests ok, but it still doesn't run, there's a couple more possible causes to check: -Sometimes the connector for the tailgate motor will test ok, but not make contact when plugged in. You might try backprobing the motor side wires with the plug connected. On mine I removed it & soldered the connections. -It's possible for a damaged wire to carry enough load to show 12v on a tester, but not enough to operate the motor. Look for worn areas, especially in the loom between the body & the tailgate.

B- If it runs but doesn't move when wired directly to the battery, in addition to your electrical problem, the torque pins in the drive gear are probably broken too. Run the electrical tests in section "A" above, & see the torque pin, Steve83's Tailgate Tech, & Adrianspeeder's links above for the torque pin replacement.

C- If it doesn't run at all when wired directly to the battery, it sounds like it's time for a new motor. See Steve83's

link ... & use the info for removing & replacing the motor. On my truck there were multiple bad connections, so it was hard to isolate the problem. Someone before me used a ton of crimp connectors . Basically I ended up removing them & soldering all the connections, & eliminating the corroded plug to the motor..."

Source: by ElKabong (Ken, El Kabong) "

For posterity,, TG Re-Wire with Relays @

https://www.fullsizebronco.com/threads/tailgate-rewire-works-100x-better.361210/#post-5214114