You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

460/C6 swap-in progress!!!

- Thread starter Justshootme84

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Picked up a reman F350 booster and master cylinder from Rock Auto. Was going to use the stock Bronco brake lines, but they're toast, so I pulled evrything out last weekend, and will bend my own lines to fit as needed.

mbtech2003

New member

thats the best thing to do there lol ford brake lines never rust.....Picked up a reman F350 booster and master cylinder from Rock Auto. Was going to use the stock Bronco brake lines, but they're toast, so I pulled evrything out last weekend, and will bend my own lines to fit as needed.

must of made them out of the same metal as the tailgate haha

JSM84 I have a chance to pick up a 390 w/tri power all rebuilt from my brothers 69 boss mustang He was doing a ground up restoration while the body was in the shop someone stole it and now he just has the motor would this be the same type of swap as the 460 your doing? oh ya its going in a 95 XLT 302 5.0 If you have any ideas that would be greatNow working on swapping the complete drivetrain from an 88 F-350 4WD into my 84 Bronco. Pulled the 460, C6, and B-W 13-56 this past weekend from the 88, taking some time to clean off the grime. Also going to install the front Dana60 and rear Sterling 10.25" under the Bronco, those come out weekend after next. Will post a few pics and tips along the way, and welcome any helpful advice on the swap. JSM84

Update: What's that rumblin' noise???

Been working the past few months on the wiring harness and brakes. Rear brake lines, proportioning valve, booster and MC installed. Just need a few lines for the front to be done. Started installing the wiring harness awhile back, as it took a rather long time to gather up parts and endure the winter cold. I mounted the fuse panel under the dash in the center on the firewall, about right below where the factory speaker used to sit. I mounted the panel on a ceiling fan bracket to keep it off of the firewall a bit, and this makes it easier to route the wiring. I pulled out about half of the harness that I'm not using to simplify the install.

This past weekend, We wired up the fuel pump and relay kit, the starter, HEI coil wire, battery and sstarter solenoid wiring. Added some oil to the motor and hooked up a battery. After some troubleshooting, checking for fuel leaks (There were none), the engine cranked over. Opened up the choke, and VROOM!!! Just ran it for about 20 seconds, shut it off, then ran it again for 15-20 secs, but the 460 still runs like a freakin' sewing machine. Big thanks and "ATTABOY"s go out to TX460Bronco, Skittles and BigT2317 for helping me out on Sunday. JSM84

Been working the past few months on the wiring harness and brakes. Rear brake lines, proportioning valve, booster and MC installed. Just need a few lines for the front to be done. Started installing the wiring harness awhile back, as it took a rather long time to gather up parts and endure the winter cold. I mounted the fuse panel under the dash in the center on the firewall, about right below where the factory speaker used to sit. I mounted the panel on a ceiling fan bracket to keep it off of the firewall a bit, and this makes it easier to route the wiring. I pulled out about half of the harness that I'm not using to simplify the install.

This past weekend, We wired up the fuel pump and relay kit, the starter, HEI coil wire, battery and sstarter solenoid wiring. Added some oil to the motor and hooked up a battery. After some troubleshooting, checking for fuel leaks (There were none), the engine cranked over. Opened up the choke, and VROOM!!! Just ran it for about 20 seconds, shut it off, then ran it again for 15-20 secs, but the 460 still runs like a freakin' sewing machine. Big thanks and "ATTABOY"s go out to TX460Bronco, Skittles and BigT2317 for helping me out on Sunday. JSM84

love_my_bronco

New member

i just want you to know that you have inspired me to upgrade the sh#t out of my 83 bronco!! hmm i just dont know what yet. how long has this project taken you so far bud?Update: What's that rumblin' noise???

Been working the past few months on the wiring harness and brakes. Rear brake lines, proportioning valve, booster and MC installed. Just need a few lines for the front to be done. Started installing the wiring harness awhile back, as it took a rather long time to gather up parts and endure the winter cold. I mounted the fuse panel under the dash in the center on the firewall, about right below where the factory speaker used to sit. I mounted the panel on a ceiling fan bracket to keep it off of the firewall a bit, and this makes it easier to route the wiring. I pulled out about half of the harness that I'm not using to simplify the install.

This past weekend, We wired up the fuel pump and relay kit, the starter, HEI coil wire, battery and sstarter solenoid wiring. Added some oil to the motor and hooked up a battery. After some troubleshooting, checking for fuel leaks (There were none), the engine cranked over. Opened up the choke, and VROOM!!! Just ran it for about 20 seconds, shut it off, then ran it again for 15-20 secs, but the 460 still runs like a freakin' sewing machine. Big thanks and "ATTABOY"s go out to TX460Bronco, Skittles and BigT2317 for helping me out on Sunday. JSM84

Last edited by a moderator:

It'll be 3 years this July. I blew up the 351W H.O. in 7/05, and bought the F-350 in 7/06. Had to look, I started this thread in 8/06, so it's been over a year-1/2. I work slow, as it took two years to put my rollcage in the Bronco. I really only have the Winter months to do major mods, and if the weather is bad it just delays things further. You can read up on the mods I did the first 4 years, like the lift kit and Shaker intake, in the featured ride article:

http://broncozone.com/forums/index.php?showtopic=2882

But I agree, nothing inspires you more to keep working than hearing a big block motor rumble with no exhaust!!! JSM84

http://broncozone.com/forums/index.php?showtopic=2882

But I agree, nothing inspires you more to keep working than hearing a big block motor rumble with no exhaust!!! JSM84

Last edited by a moderator:

love_my_bronco

New member

**** yea!! thank you! so a 460 y did you chose that over lets say a diesel or something? just wondering.

Look at the engine specs for a 351W vs the 460 vs a Ford PSD diesel, as well as the weight. The 460 has gobs of torque, the horsepower can be bumped up rather easily, it's a rather simple swap and the weight is not much more than the 351W. While a diesle would have more torque, it would be alot more weight and involve alot more work to fit it into the Bronco.**** yea!! thank you! so a 460 y did you chose that over lets say a diesel or something? just wondering.

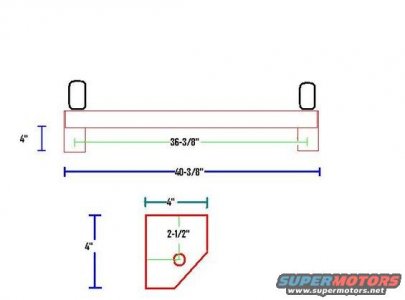

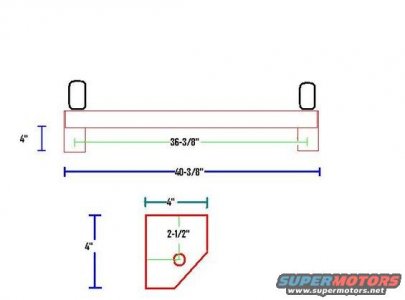

Just added some measurements to my SFo gallery for those who asked for them:

The crossmember is 2"x4"x1/4"thick rectangular steel tubing, and the spring hangers are made from 4"x4"x1/4" thick square tubing. The xmbr is fully welded, with gussets added. To mount it under the frame horns, I found two holes in the frame that were perhaps for the front sway bar brackets. I drilled a pilot hole in the xmbr on each side, so I could aling it and check axle location. The xmbr was moved as far forward as possible to the front of the frame horns, then welded to the frame with 1/4" plates on the sides for more support. JSM84

The crossmember is 2"x4"x1/4"thick rectangular steel tubing, and the spring hangers are made from 4"x4"x1/4" thick square tubing. The xmbr is fully welded, with gussets added. To mount it under the frame horns, I found two holes in the frame that were perhaps for the front sway bar brackets. I drilled a pilot hole in the xmbr on each side, so I could aling it and check axle location. The xmbr was moved as far forward as possible to the front of the frame horns, then welded to the frame with 1/4" plates on the sides for more support. JSM84

thats a great project jsm and a super sweet bronco. very clean.

One of the best upgrades on the 460(for the price) is a pre emissions timing gear set. Not sure if you/ve swapped that out in the long list of other upgrades you have there but after 71 they timing was really crappy to meet emission standards. I think the timing gear along picks up about 50hp There was a few articles awhile back that had the BB ford pushing 500hp for under 2grand i think. I want to say it was hot rod magazine.

There was a few articles awhile back that had the BB ford pushing 500hp for under 2grand i think. I want to say it was hot rod magazine.

One of the best upgrades on the 460(for the price) is a pre emissions timing gear set. Not sure if you/ve swapped that out in the long list of other upgrades you have there but after 71 they timing was really crappy to meet emission standards. I think the timing gear along picks up about 50hp

thank you, I do plan some future upgrades like that timing gear change, swap the heads, some porting.

just got done this weekend working on the B-w 13-56 t-case off the 88 F-350, changing from the slip yoke to a fixed yoke rear output. The bearings were toast, replaced those, new seals, and the rear shaft/tailhousing from an electric, bronco 13-56 t-case. Front driveshaft is re-built, too, since it was out. Will have to make one for the rear by swapping out the bigger yokes. look for some driving and flex pics coming soon!!! JSM84

just got done this weekend working on the B-w 13-56 t-case off the 88 F-350, changing from the slip yoke to a fixed yoke rear output. The bearings were toast, replaced those, new seals, and the rear shaft/tailhousing from an electric, bronco 13-56 t-case. Front driveshaft is re-built, too, since it was out. Will have to make one for the rear by swapping out the bigger yokes. look for some driving and flex pics coming soon!!! JSM84

Update:hey this might be a good idea usinga helicoil. go to helicoil.com to find out more. all it requires is a little drilling and tapping new threads sometimes works better than the original look into it at helicoil.com

Ran into a big problem with the 460. WHile cleaning it up a bit and looking for the source of a small oil leak, I noticed a few bolts missing from the exhaust manifolds on both sides. Both bolts on no. 1 and no. 8 cylinders!!! One bolt was missing per side, but the other two were each broke off by the P.O. inside the heads... :angry:

I was able to drill out the remains of both bolts, and re-tap the threads. I'll try to use a exhaust manifold stud and Loctite for each of these two holes, and hope the headers will fit without leaking. I spent about two days on this and just finding a 3/8" tap that would work, but it beats paying a machine shop $75 per hole.

And the oil leak appears to be from the intake manifold gasket at the rear of the motor. I need to replace one freeze plug, as it looks kinda rusty. I also ordered a special carb spacer/adapter to allow mounting a carb on top of the EFI intake manifold. THat way, I can use the intake and E7TE heads. Just need to change out the ditributor, too. JSM84

Pic of the motor, and trying to remove one broken bolt with an extractor. Too tight, and the extraxtor stripped out the hole drilled into the piece of the bolt. Also tried an easy-out with no success.

Did some more work on the Bronco over the 3-day weekend, in between watching the INDY 500 and Coca-Cola 600 races. Removed the NP208 and bolted up the B-W 13-56 t-case, getting good at swapping these out! I was able to use the NP208 shifter and tranny mount, then attach the B-W13-56 linkage bar to the t-case shift selector. The B-W bar is about 2" shorter than that for the NP. The t-case shifts like butter!!!

Still having issues with the front driveshaft, dangit. I had a new CV joint welded onto, but it doesn't have very much range of movement either. may be able to clearance a few spots to help a bit. The ds is also about 2" short, needs to be 35" long, so it barely reaches the front pinion yoke at full extension. Can't bolt it up anyhow, since it still hits the tranny crossmember. It's too long to use for the rear, but may fit once i add 4 more inches of lift. All the spare driveshafts I have for the rear are also too long, it needs to be 31". I think I'll make some custom driveshafts from the spare yokes and suare tubing, since this is a trail rig only. Will also have to modify the crossmember to clear the front ds.

Almost finished with the brake lines, just need a hose for the front center drop. Found some stock front hoses to the calipers, and welded a brakcet to the trac bar bracket on the driver's side of the front axle. Was able to bolt a line bracket on the passngr side to the u-bolt mounting plate. These will be modified later when I flip the u-bolts on the D60 front axle.

Also hooked up the throttle cable and tranny kickdown rod for the Holley carb. Robbed a few parts of the old HLy4180 from my 351W, too, for the return spring and such. Getin' closer!!! JSM84

Still having issues with the front driveshaft, dangit. I had a new CV joint welded onto, but it doesn't have very much range of movement either. may be able to clearance a few spots to help a bit. The ds is also about 2" short, needs to be 35" long, so it barely reaches the front pinion yoke at full extension. Can't bolt it up anyhow, since it still hits the tranny crossmember. It's too long to use for the rear, but may fit once i add 4 more inches of lift. All the spare driveshafts I have for the rear are also too long, it needs to be 31". I think I'll make some custom driveshafts from the spare yokes and suare tubing, since this is a trail rig only. Will also have to modify the crossmember to clear the front ds.

Almost finished with the brake lines, just need a hose for the front center drop. Found some stock front hoses to the calipers, and welded a brakcet to the trac bar bracket on the driver's side of the front axle. Was able to bolt a line bracket on the passngr side to the u-bolt mounting plate. These will be modified later when I flip the u-bolts on the D60 front axle.

Also hooked up the throttle cable and tranny kickdown rod for the Holley carb. Robbed a few parts of the old HLy4180 from my 351W, too, for the return spring and such. Getin' closer!!! JSM84

Last edited by a moderator:

I was just curious on how to do a wiring harness. I installed a 460 efi from a 90 into my 77 and i couldnt get the thing to burn any gas would just fire on either then shut off but im thinking about converting it to carb but i wasnt sure how hard that would be as far as wiring. It seemed pretty simple when you did yours i was wondering what it involved.

I was just curious on how to do a wiring harness. I installed a 460 efi from a 90 into my 77 and i couldnt get the thing to burn any gas would just fire on either then shut off but im thinking about converting it to carb but i wasnt sure how hard that would be as far as wiring. It seemed pretty simple when you did yours i was wondering what it involved.

do you have enough fuel pressure? If you arent Esavy i think painless makes a harness for a few hundred bucks.

If you're running the fuel injection, you need alot higher pump pressure than for a carb, somewhere around 25-40 psi vs 4-7 psi. I have about 5 psi at idle, using an electric fuel pump and pressure regulator with a gauge.I was just curious on how to do a wiring harness. I installed a 460 efi from a 90 into my 77 and i couldnt get the thing to burn any gas would just fire on either then shut off but im thinking about converting it to carb but i wasnt sure how hard that would be as far as wiring. It seemed pretty simple when you did yours i was wondering what it involved.

I just finished doing a continuity test on all the wiring last weekend, and all looks good. Is it hard to wire up? For me, yes, but I had my brother and a couple other folks help out who are good at electrical stuff. JSM84

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 65

- Views

- 27K