Jbrownjr

Member

She was running rough a few months ago after leaving the mechanic shop. We'd already replaced every solenoid and relay that he thought might be the issue and recommended a new main wiring harness.

We found a good donor (86 B2 2.9L Automatic 4x4...for our B2 2.9L Manual 4x4). Now she won't start. Cranks, but:

I tried grounding the Fuel Pump slot on the ODB-1 connector, but no change.

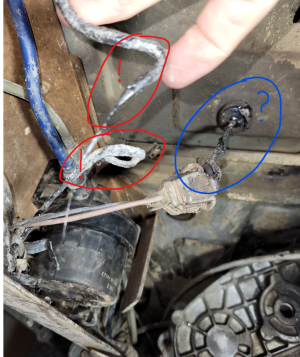

Jumping between the yellow and Orange/Lt Blu the high-pressure pump runs. Seemed like a bad Fuel pump relay. We replaced that...no pump action when turning the key.

Seems the EEC ought to ground pin #22 to close the circuit for a few seconds when the key is on/start, but it doesn't.

Testing the Tan/Lt green wire we found it's grounded all-the-time. (Confirmed that the ODB-1 Fuel Pump slot is, of course, also already grounded even though it shouldn't be?) it should only be grounded for a few seconds WHEN the key is turned?

Testing for a grounded out wire between the fuel pump relay connector and the EEC (Tan/Lt green wire), I tested for continuity. No shorts.

We happened to have a 2nd EEC, so I swapped them out. No change.

Either I'm misunderstanding the expected behavior, or I'm just stumped on where to look next.

Any ideas?

We found a good donor (86 B2 2.9L Automatic 4x4...for our B2 2.9L Manual 4x4). Now she won't start. Cranks, but:

- She won't fire

- Fuel pumps won't turn on

I tried grounding the Fuel Pump slot on the ODB-1 connector, but no change.

Jumping between the yellow and Orange/Lt Blu the high-pressure pump runs. Seemed like a bad Fuel pump relay. We replaced that...no pump action when turning the key.

Seems the EEC ought to ground pin #22 to close the circuit for a few seconds when the key is on/start, but it doesn't.

Testing the Tan/Lt green wire we found it's grounded all-the-time. (Confirmed that the ODB-1 Fuel Pump slot is, of course, also already grounded even though it shouldn't be?) it should only be grounded for a few seconds WHEN the key is turned?

Testing for a grounded out wire between the fuel pump relay connector and the EEC (Tan/Lt green wire), I tested for continuity. No shorts.

We happened to have a 2nd EEC, so I swapped them out. No change.

Either I'm misunderstanding the expected behavior, or I'm just stumped on where to look next.

Any ideas?