yo H,

I missed this page 2 last night, I believe.

I did find the "jack" info tho later last night;

http://www.diesel-dave.com/vehic/manual/stj/stj30029.htm

Ask as much as you need to; we all had to ask as well as I do now for other things I never did or saw done.

Now, I think the engine should come out. Some may have done this w/engine in, but may as well pull it and check everything else. Such as;

"Main Bearing Bore Alignment

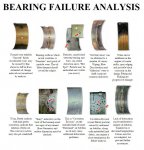

Main bearing bore misalignment may be suspected in cases of premature bearing wear if one bearing wears considerably more than the others or bearings wear cone-shaped.

...NOTE: Bearings are not available with oversize outside diameters to allow line boring. Inspect bearings. Blue dye should be deposited evenly on all bearings. If dye appears on only one side or bottom of bearing or not at all, cylinder block is distorted and should be replaced..."

http://www.diesel-dave.com/vehic/manual/stj/stj30025.htm#extract_349

Sorry, did not foresee other issues that may pop-up and especially your determination to do this work and keep at it until you are satisfied. And that is VERY GOOD~

This is by Chilton; "

Crankshaft Endplay/Connecting Rod Side Play

Handle the crankshaft carefully to avoid damage to the finish surfaces.

1.Clean the crankshaft with solvent and blow out all oil passages with compressed air. On the 4.9L engine, clean the oil seal contact surface at the rear of the crankshaft with solvent to remove any corrosion, sludge or varnish deposits.

2.Use crocus cloth to remove any sharp edges, burrs or other imperfections which might damage the oil seal during installation or cause premature seal wear.

Do not use crocus cloth to polish the seal surfaces. A finely polished surface may produce poor sealing or cause premature seal wear.

3.Inspect the main and connecting rod journals for cracks, scratches, grooves or scores

4.Measure the diameter of each journal at least four places to determine out-of-round, taper or undersize condition.

5.On an engine with a manual transmission, check the fit of the clutch pilot bearing i the bore of the crankshaft. A needle roller bearing and adapter assembly is used as a clutch pilot bearing. It is inserted directly into the engine crank shaft. The bearing and adapter assembly cannot be serviced separately. A new bearing must be installed whenever a bearing is removed.

6.Inspect the pilot bearing, when used, for roughness, evidence of overheating or loss of lubricant. Replace if any of these conditions are found."

Here are some crankshaft counterweight pics; for a 351M but sim.

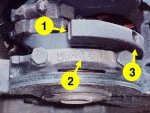

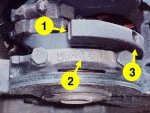

"More Crankshaft Casting Marks

1. (and 3.) Machined and drilled parts of the rear crankshaft counterweight. These are adjustments to balance the crankshaft at the factory.

2. Cleveland Foundry (CF) mark on #5 main bearing cap. The #5 main bearing cap is usually not marked because it is unique, wider than the other main bearing caps, with a groove for the rear main seal. Note that the main bearing cap in this D7TE engine is the original 400 design from 1971 (D1AE-AA).

http://grantorinosport.org/BubbaF250/parts/pics02.html