This is long, sorry.

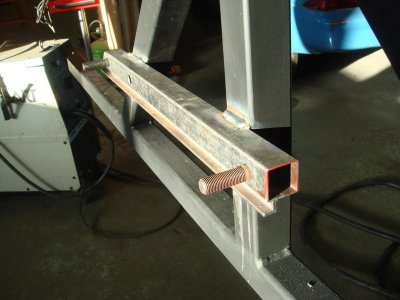

My nice rusty 1/4" 4x6 6 foot long metal beam for 90 bucks

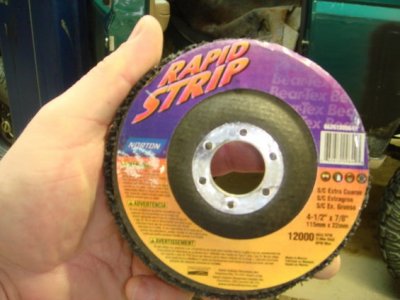

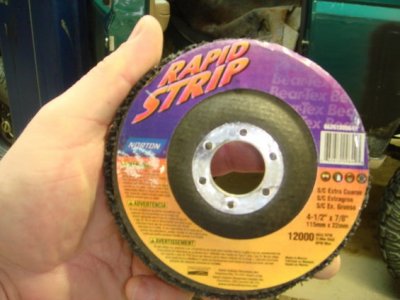

I hate rust so lets get rid of it with one of these Rapid Strip Wheels.

Oh that looks so much better!

To keep the rust from coming back while I build I coated it with a can of rust stop

Drilling some pilot holes for the jigsaw

And enlarge them some

Time for the jigsaw, just connect the dots. By the way I have the wrong blade only good for 1/8" but did fine on the 1/4" anyways.

Now I have a square hole, did a little hand filing for a perfect fit.

Test fitting the square tubing, it slides all the way through without problem and is square.

Time to cut the ends, ran out of jigsaw blades so I'll use a cutting disk in my grinder. Fun taking pics and cutting at the same time.

Ok the end is cut off

and this is where I left it.

Ok I'm home now, so time to post some pics. Ok I already showed you how you can do this with basic hand tools such as a jigsaw, but enough of that time for the big toys.

Using the heavy 60 year old band saw I start on the mounts. Cutting these into 5x8"

I notch it down an inch at the end. A little trick I do to make sure each bracket is the same, I cut them out and than clamp them together in a vice and run a grinder around the edges to make perfect replicas of each other.

Marking the receiver for the pin hole 2 1/2" from the end.

Perfect!

I took my measurements from my old hitch. Pin is 2 1/2" in and 8" deep. Sorry for the bad pics, it was hard to hold the tape and take a pic while bending over. lol

Test fit, looks like it'll work just fine

Sticks out the back side just enough to weld.

Ok more tomorrow.

I was able to but about 4hrs into the bumper today.

Some 1"x3" I bought, seeing if the band saw can cut

And yes it can, cutting these into 7" lengths

Drilling 1/2" hole and working my way up to 7/8"

7/8" drill bit

Tapering the ends

grinding them smooth

Dam they look pretty good if i don't say so myself!:rockon

Ok making the bumper thingy that goes around the receiver, this should be 10" long.

Apply some heat and taking a pic at the same time.

Get it nice and hot

And bend it around

and repeat for the next corner

And weld the ends together and to the reciever

Just thought this up

Drawing out where all the pieces will go

Welding in the receiver and the stinger - would you call it a stinger?

not bad for 1/2 a day.:drinkbud

Was back in the shop today, but had to get my bronco back together so I only had about an hour to spare on the bumper.

I cut out the holes to mount the cleaves through and weld.

Looking pretty good and my coffee was still hot.

Back side of the cleaves, I let it hang out out an inch so I can catch it with mounts I made and weld them direct. These bad boys are not going anywheres!

So now I need to cap the ends and wait for my tire bearing hinge thingy to come in.

All righty I now have my tire carrier spindle bearing kit.

Hope to get this installed today or tomorrow.

Ok today was a good day, just finished tacking on the bracket and my buddy Ted showed up just in time to lift the dam thing and see if it even fits! :director:

And its fits perfectly on the first try! :yo:

Ok time to weld her up, Ted made up some extra brackets while I weld. :whip:

Don't think it'll fall off.

Ted and I worked on the tire rack today, thanks Ted for the hand!

we notched the tubing for the collar. Tubing is 3/16"

couple tacks to holder it to geather.

Start building the uprights out of 1/8" square tubing.

And than we jump a head, sorry.

A little more work on the rear bumper. Smoothed out some of the welds, added the studs for the wheel bracket and added some more bracing.

Some pics of the lock

Little under the weather today, but i did manage to mount my trailer light plug into the bumper and thread holes for the license plate.

Found a piston that will work just fine, but word of warning - you don't want it any shorter than this one! It just works for this.

Heres the piston

The stud is built in, so it shouldn't pop off.

about 19" in length

Took some figuring out but it worked first try.

Open

I'm happy with that, and let me tell you that little bugger is some strong.

Time to get some paint on this sucker!

Brushed out the carbon and rust spots from the welds

Almost forgot about the trail chain hook up. :doh0715:

Striped the whole thing down to get the burnt paint and grease off.

I coating it with Rust Bullet for good protection, it'll be the primer.

Doesn't look to bad.

My nice rusty 1/4" 4x6 6 foot long metal beam for 90 bucks

I hate rust so lets get rid of it with one of these Rapid Strip Wheels.

Oh that looks so much better!

To keep the rust from coming back while I build I coated it with a can of rust stop

Drilling some pilot holes for the jigsaw

And enlarge them some

Time for the jigsaw, just connect the dots. By the way I have the wrong blade only good for 1/8" but did fine on the 1/4" anyways.

Now I have a square hole, did a little hand filing for a perfect fit.

Test fitting the square tubing, it slides all the way through without problem and is square.

Time to cut the ends, ran out of jigsaw blades so I'll use a cutting disk in my grinder. Fun taking pics and cutting at the same time.

Ok the end is cut off

and this is where I left it.

Ok I'm home now, so time to post some pics. Ok I already showed you how you can do this with basic hand tools such as a jigsaw, but enough of that time for the big toys.

Using the heavy 60 year old band saw I start on the mounts. Cutting these into 5x8"

I notch it down an inch at the end. A little trick I do to make sure each bracket is the same, I cut them out and than clamp them together in a vice and run a grinder around the edges to make perfect replicas of each other.

Marking the receiver for the pin hole 2 1/2" from the end.

Perfect!

I took my measurements from my old hitch. Pin is 2 1/2" in and 8" deep. Sorry for the bad pics, it was hard to hold the tape and take a pic while bending over. lol

Test fit, looks like it'll work just fine

Sticks out the back side just enough to weld.

Ok more tomorrow.

I was able to but about 4hrs into the bumper today.

Some 1"x3" I bought, seeing if the band saw can cut

And yes it can, cutting these into 7" lengths

Drilling 1/2" hole and working my way up to 7/8"

7/8" drill bit

Tapering the ends

grinding them smooth

Dam they look pretty good if i don't say so myself!:rockon

Ok making the bumper thingy that goes around the receiver, this should be 10" long.

Apply some heat and taking a pic at the same time.

Get it nice and hot

And bend it around

and repeat for the next corner

And weld the ends together and to the reciever

Just thought this up

Drawing out where all the pieces will go

Welding in the receiver and the stinger - would you call it a stinger?

not bad for 1/2 a day.:drinkbud

Was back in the shop today, but had to get my bronco back together so I only had about an hour to spare on the bumper.

I cut out the holes to mount the cleaves through and weld.

Looking pretty good and my coffee was still hot.

Back side of the cleaves, I let it hang out out an inch so I can catch it with mounts I made and weld them direct. These bad boys are not going anywheres!

So now I need to cap the ends and wait for my tire bearing hinge thingy to come in.

All righty I now have my tire carrier spindle bearing kit.

Hope to get this installed today or tomorrow.

Ok today was a good day, just finished tacking on the bracket and my buddy Ted showed up just in time to lift the dam thing and see if it even fits! :director:

And its fits perfectly on the first try! :yo:

Ok time to weld her up, Ted made up some extra brackets while I weld. :whip:

Don't think it'll fall off.

Ted and I worked on the tire rack today, thanks Ted for the hand!

we notched the tubing for the collar. Tubing is 3/16"

couple tacks to holder it to geather.

Start building the uprights out of 1/8" square tubing.

And than we jump a head, sorry.

A little more work on the rear bumper. Smoothed out some of the welds, added the studs for the wheel bracket and added some more bracing.

Some pics of the lock

Little under the weather today, but i did manage to mount my trailer light plug into the bumper and thread holes for the license plate.

Found a piston that will work just fine, but word of warning - you don't want it any shorter than this one! It just works for this.

Heres the piston

The stud is built in, so it shouldn't pop off.

about 19" in length

Took some figuring out but it worked first try.

Open

I'm happy with that, and let me tell you that little bugger is some strong.

Time to get some paint on this sucker!

Brushed out the carbon and rust spots from the welds

Almost forgot about the trail chain hook up. :doh0715:

Striped the whole thing down to get the burnt paint and grease off.

I coating it with Rust Bullet for good protection, it'll be the primer.

Doesn't look to bad.

Last edited by a moderator: