ok guys, I need help rather quickly.I can't borrow anyone's vehicle this week to get to work and I got my heads back on my truck and I had taken off old coil pigtail because clips were broken on it and I can't remember for nothing how the wires reconnect. The harness from the truck has a red wire with a stripe and a solid red wire and the other wire looks brown and on my new pigtail I have a red wire with a stripe coming out of one connector and 2 green wires coming out of the other connector.and one with a stripe. Can somebody refresh my memory on how these reconnect. I feel like a ******* but the truck has been down for about 5 months because of Autozone destroying my heads because they sold me wrong spark plugs and it cracked spark plug holes but they did finally pay me for them.So, help!!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pigtail connector for coil

- Thread starter rogmit

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

yo Rog;

Wiring Diagram

1992 Bronco 5.8

http://www.revbase.com/BBBMotor/Wd/DownloadPdf?id=33067

Coil & connector pic

Red/Light Green on Right looking from front bumper.

I'll add more info later and if better half comes home soon with her cell, will snap another pic.

Wiring Diagram

1992 Bronco 5.8

http://www.revbase.com/BBBMotor/Wd/DownloadPdf?id=33067

Coil & connector pic

Red/Light Green on Right looking from front bumper.

I'll add more info later and if better half comes home soon with her cell, will snap another pic.

hi miesk5, well I got the truck startedbut there is no power on acceleration even though the idle is smooth,so I'm guessing the timimg is off.I tried setting according to a previous forum and it fired right up but no power. So, I guess the timing is still off. I'm setting it 10 degrees before TDC and then I set the distributor rotor according to your directions but no acceleration power. I know it has something to do with the timing but I have been screwing with this all day and I'm loosing daylight. So, it is a 1992 ford bronco 5.8 liter gt40 heads that I had rebuilt,Autozone blew up my Edelbrock heads but paid me for them. If I',

m standing at the front of the truck, I want the distributor rotor pointing towards this engine correct,then according to your pctures of the installation of a distributor the #1 spot on the distributor cap should be at the front of the truck correct.Let me know as soon as possible what you think because I need to drive this to work tomorrow and I got to have it running tonight.Thanks for the pigtail wiring diagrams also, now I just need some more help.

m standing at the front of the truck, I want the distributor rotor pointing towards this engine correct,then according to your pctures of the installation of a distributor the #1 spot on the distributor cap should be at the front of the truck correct.Let me know as soon as possible what you think because I need to drive this to work tomorrow and I got to have it running tonight.Thanks for the pigtail wiring diagrams also, now I just need some more help.

yo Rog,

Did you pull the SPOUT connector on the inner fender prior to setting?

See How to Set the timing on an EFI Ford by Ryan M

http://web.archive.org/web/20130817010931/http://oldfuelinjection.com/?p=71

I have to go to PT, then see a Doc;

Others here will help you more soon, I'm sure!

Did you pull the SPOUT connector on the inner fender prior to setting?

See How to Set the timing on an EFI Ford by Ryan M

http://web.archive.org/web/20130817010931/http://oldfuelinjection.com/?p=71

I have to go to PT, then see a Doc;

Others here will help you more soon, I'm sure!

Yo miesk5, yes I did pull the spout and I know the timing is wrong because when I set the distributor in a certain way, I'm getting the opposite side of the harmonic balancer even though the truck starts right up. You don't see the timing marks at all.But, is the little like peep hole on the top of distributor cap suppose to be atthe back of the engine because the pictures in a previous forum show the distributor cap pointing at the front of the engine, putting the #1 spark plug at the front of the engine and not the back like I have it. This is the last thing I need to do so I can drive my truck.MSD had to replace the distributor because of a bad pickup and my old distributor was marked before I pulled it out.So, I know it is a timing issue but I just don't know how to correct it.So, your help would be much appreciated it.

yo Rog,

ok, good!

There are a couple ways to find top dead center.

Take the #1 Spark plug out..

Turn the motor over with a socket on the crank bolt(turn in the direction the motor spins)

When you start to feel air coming out of the plug hole the piston will be coming up to TDC.

At this point I usually stick a ***** driver in the cylinder as I am turning the motor over and as soon as the piston stops going up all the way it is at TDC.

Other easy way is when the air starts coming out line up you timing mark to zero (if your timing mark is correct.)

Like I said there are other ways see what other people say, they may have a better way

check for compression, then use the straw to get it at the top. Otherwise you may have it at TDC on the exhaust stroke

drop a drinking straw into the spark plug hole & watch it. It can't hurt the threads or the piston, like a metal object could

This is by Ford;

Section 03-07A: Ignition, Distributor

1996 F-Series and Bronco with Gasoline Engines Workshop Manual

REMOVAL AND INSTALLATION

Distributor

Removal

1.Align timing pointer with top dead center (TDC) on crankshaft vibration damper.

2.Mark position of No. 1 cylinder wire tower on distributor base. Mark will provide an alignment reference when reinstalling the distributor (12127).

3.On a 4.9L engine, loosen distributor cap hold-down screws. On all V-8 engines, disengage distributor cap hold-down clips.

4.Lift distributor cap (12106) with attached wire set straight off distributor to prevent damage to rotor blade and spring. On V-8 engines, remove attaching screws and base adapter.

5.Position distributor cap and attached wire set aside so as not to interfere with removal.

6.Check if distributor rotor blade is pointing toward the marked position on the distributor base adapter (12A217). If distributor rotor blade is pointing one-half a revolution off, rotate crankshaft one full revolution and realign timing pointer with TDC on crankshaft vibration damper.

7.Disconnect wiring harness at distributor.

8.Remove distributor rotor (12200) by pulling upward on distributor rotor from distributor shaft.

9.Remove distributor hold-down bolt and clamp.

10.Remove distributor from cylinder block by pulling upward with a slight side-to-side twist.

11.Cover distributor opening in cylinder block with a clean shop towel to prevent the entry of foreign material into engine.

Installation

1.NOTE: When installing distributor, No. 1 piston must be at TDC of the compression stroke.

Visually inspect distributor. O-ring should fit tightly onto housing free of cuts. Drive gear should be free of nicks, cracks or excessive wear. The distributor shaft should rotate freely, without any binding.

2.Lubricate distributor gear teeth with a coating of Engine Assembly Lubricant D9AZ-19579-D or equivalent fresh motor oil meeting Ford specification ESR-M99C80-A.

3.Align locating boss and fully seat distributor rotor on distributor shaft.

4.Rotate distributor shaft so that distributor rotor blade is pointing toward marked position on distributor base adapter.

5.Install distributor into cylinder block with a slight side-to-side twist.

6.NOTE: If the vane and vane switch assembly can not be kept on the leading edge after installation, remove the distributor from cylinder block by pulling upward enough for the distributor gear to disengage from the camshaft gear. Rotate distributor rotor enough so the gear will align on the next tooth of the camshaft gear.

Rotate distributor in engine to align leading edge of armature vane to vane switch assembly. Verify that distributor rotor blade is pointing toward marked position on distributor base adapter.

7.Install distributor hold-down clamp and bolt.

8.On all V-8 engines, position adapter base and install attaching screws.

9.Position distributor cap with attached wire set straight on distributor to prevent damage to rotor blade and spring.

10.On a 4.9L engine, tighten distributor cap hold-down screws to 2.0-2.6 Nm (18-23 lb-in). On all V-8 engines, secure distributor cap using spring clips.

11.Connect distributor to wiring harness.

12.Set initial timing according to procedures in Powertrain Control/Emissions Diagnosis Manual OBDI or OBDII.

13.Without moving timing adjustment, tighten distributor hold-down bolt and clamp to 23-34 Nm (17-25 lb-ft).

and this is by SANDY;

"...First off, for those who don't know, timing is what controls when the sparkplug fires in comparison to where the piston is in the cylinder. You want it to fire while the piston is still compressing the fuel-air mixture, just before it starts going back down. When the piston is at the very top of the stroke, that's called Top Dead Center (TDC). Normal base timing for the `94 5.0 is 10 degrees BTDC (Before TDC). That means that the sparkplug fires when the crank still has 10 degrees to turn before reaching TDC. That's what the factory chose for the most efficient burn. With this enhanced ignition system, we can fire even earlier than that, and burn even more of the fuel, more completely.

First thing to do is to make the timing marks readable. There are two parts to the timing marks: The degree marks on the harmonic balancer (on the front end of the crankshaft, behind the main pulley), and the pointer (fixed to the block). We'll make the degree marks readable first. Get out your remote start switch, and connect it across the starter solenoid.

Disconnect the coil wire so the engine won't start.

While you're at it, put the parking brake on, chock the wheels, and make sure the transmission is in Park (neutral if a stick shift).

Stand off to the side and hit the remote starter switch a couple of times, make sure that the engine turns over *without* the truck leaping forward and crushing you to death.

Put on some eye protection. I like the faceshield because it keeps the rust out of my mouth.

Once you're pretty sure you're not going to **** yourself, crawl under and lay on your back under the front of the truck. Feed the starter switch down to where you can use it (keeping the cables out of the belt and fan), and bump the engine around until you can see the degree marks on the harmonic balancer.

Make them visible. You could clean and paint them (what I wish I'd done), or you could put on a timing tape, like I did. (I only used part of it, because I couldn't get it all on, and only needed part of it.)

http://www.supermotors.org/getfile/306365/fullsize/timtape.jpg

Go back up top, disconnect the remote starter switch. Reach in with a paint pen or a q-tip or something and paint the end of the pointer. (For reference, at the top of this picture is the bottom of the idler pulley, at the bottom left is the top of the tensioner pulley, and at the bottom right is the top of the water pump pulley.)

Don't loosen it yet, though, we need to warm up the engine. Put everything back on that you took off (neg battery cable, coil wire, intake tube), and fire it up. Let it get up to normal operating temperatures. Wait for the thermostat to open (when the top radiator hose goes hot). Shut it down.

Find your SPOUT connector. Here's mine, the light gray thing in the red circle. That thing above it is the cruise control servo. It's in the rear driverside corner of the engine compartment. Just unlatch the latches, pull the gray tab out of the connector, and put it somewhere safe.

And here's the signal pickup clamped around the #1 wire:

Watch your wires so they don't get into the fan or belt. Point the timing light at the timing pointer, start up the engine, and the strobe light in the timing light will fire every time the #1 cylinder fires, "freezing" the view in place so that you can read the timing setting. (You'd be amazed how hard it was to get this shot with an auto-focusing digital camera.)

http://www.supermotors.org/getfile/306362/fullsize/timing.jpg

Shut down the engine. Loosen the distributor clamp bolt that we discussed earlier, just enough that it allows the distributor to turn. Rotate the distributor (just grab it by the cap and turn it) clockwise to advance the timing (advance means go further BTDC, so 11 BTDC is 1 degree advanced from 10 BTDC). You're shooting for about 13 or 13.5 degrees. The picture above shows 13 degrees.

Start up again and check the timing. Shut down and tighten the clamp bolt back down when you've got the timing where you want it. Here you can see how little we actually turned the distributor (small white mark used to be under the clamp bolt).

The bolt doesn't have to be super tight, just enough so that the timing doesn't change on its own and the bolt doesn't loosen on its own.

Put the SPOUT connector back in. Check all your connections and make sure that you have re-attached everything you detached.

Take it out for a spin. Hopefully your mileage and performance will both be improved. If you hear any "pinging" (a rattling sound from the engine), especially during acceleration, you may have advanced the timing too far. Back it off a little.

http://www.supermotors.net/registry/11474/32259

ok, good!

There are a couple ways to find top dead center.

Take the #1 Spark plug out..

Turn the motor over with a socket on the crank bolt(turn in the direction the motor spins)

When you start to feel air coming out of the plug hole the piston will be coming up to TDC.

At this point I usually stick a ***** driver in the cylinder as I am turning the motor over and as soon as the piston stops going up all the way it is at TDC.

Other easy way is when the air starts coming out line up you timing mark to zero (if your timing mark is correct.)

Like I said there are other ways see what other people say, they may have a better way

check for compression, then use the straw to get it at the top. Otherwise you may have it at TDC on the exhaust stroke

drop a drinking straw into the spark plug hole & watch it. It can't hurt the threads or the piston, like a metal object could

This is by Ford;

Section 03-07A: Ignition, Distributor

1996 F-Series and Bronco with Gasoline Engines Workshop Manual

REMOVAL AND INSTALLATION

Distributor

Removal

1.Align timing pointer with top dead center (TDC) on crankshaft vibration damper.

2.Mark position of No. 1 cylinder wire tower on distributor base. Mark will provide an alignment reference when reinstalling the distributor (12127).

3.On a 4.9L engine, loosen distributor cap hold-down screws. On all V-8 engines, disengage distributor cap hold-down clips.

4.Lift distributor cap (12106) with attached wire set straight off distributor to prevent damage to rotor blade and spring. On V-8 engines, remove attaching screws and base adapter.

5.Position distributor cap and attached wire set aside so as not to interfere with removal.

6.Check if distributor rotor blade is pointing toward the marked position on the distributor base adapter (12A217). If distributor rotor blade is pointing one-half a revolution off, rotate crankshaft one full revolution and realign timing pointer with TDC on crankshaft vibration damper.

7.Disconnect wiring harness at distributor.

8.Remove distributor rotor (12200) by pulling upward on distributor rotor from distributor shaft.

9.Remove distributor hold-down bolt and clamp.

10.Remove distributor from cylinder block by pulling upward with a slight side-to-side twist.

11.Cover distributor opening in cylinder block with a clean shop towel to prevent the entry of foreign material into engine.

Installation

1.NOTE: When installing distributor, No. 1 piston must be at TDC of the compression stroke.

Visually inspect distributor. O-ring should fit tightly onto housing free of cuts. Drive gear should be free of nicks, cracks or excessive wear. The distributor shaft should rotate freely, without any binding.

2.Lubricate distributor gear teeth with a coating of Engine Assembly Lubricant D9AZ-19579-D or equivalent fresh motor oil meeting Ford specification ESR-M99C80-A.

3.Align locating boss and fully seat distributor rotor on distributor shaft.

4.Rotate distributor shaft so that distributor rotor blade is pointing toward marked position on distributor base adapter.

5.Install distributor into cylinder block with a slight side-to-side twist.

6.NOTE: If the vane and vane switch assembly can not be kept on the leading edge after installation, remove the distributor from cylinder block by pulling upward enough for the distributor gear to disengage from the camshaft gear. Rotate distributor rotor enough so the gear will align on the next tooth of the camshaft gear.

Rotate distributor in engine to align leading edge of armature vane to vane switch assembly. Verify that distributor rotor blade is pointing toward marked position on distributor base adapter.

7.Install distributor hold-down clamp and bolt.

8.On all V-8 engines, position adapter base and install attaching screws.

9.Position distributor cap with attached wire set straight on distributor to prevent damage to rotor blade and spring.

10.On a 4.9L engine, tighten distributor cap hold-down screws to 2.0-2.6 Nm (18-23 lb-in). On all V-8 engines, secure distributor cap using spring clips.

11.Connect distributor to wiring harness.

12.Set initial timing according to procedures in Powertrain Control/Emissions Diagnosis Manual OBDI or OBDII.

13.Without moving timing adjustment, tighten distributor hold-down bolt and clamp to 23-34 Nm (17-25 lb-ft).

and this is by SANDY;

"...First off, for those who don't know, timing is what controls when the sparkplug fires in comparison to where the piston is in the cylinder. You want it to fire while the piston is still compressing the fuel-air mixture, just before it starts going back down. When the piston is at the very top of the stroke, that's called Top Dead Center (TDC). Normal base timing for the `94 5.0 is 10 degrees BTDC (Before TDC). That means that the sparkplug fires when the crank still has 10 degrees to turn before reaching TDC. That's what the factory chose for the most efficient burn. With this enhanced ignition system, we can fire even earlier than that, and burn even more of the fuel, more completely.

First thing to do is to make the timing marks readable. There are two parts to the timing marks: The degree marks on the harmonic balancer (on the front end of the crankshaft, behind the main pulley), and the pointer (fixed to the block). We'll make the degree marks readable first. Get out your remote start switch, and connect it across the starter solenoid.

Disconnect the coil wire so the engine won't start.

While you're at it, put the parking brake on, chock the wheels, and make sure the transmission is in Park (neutral if a stick shift).

Stand off to the side and hit the remote starter switch a couple of times, make sure that the engine turns over *without* the truck leaping forward and crushing you to death.

Put on some eye protection. I like the faceshield because it keeps the rust out of my mouth.

Once you're pretty sure you're not going to **** yourself, crawl under and lay on your back under the front of the truck. Feed the starter switch down to where you can use it (keeping the cables out of the belt and fan), and bump the engine around until you can see the degree marks on the harmonic balancer.

Make them visible. You could clean and paint them (what I wish I'd done), or you could put on a timing tape, like I did. (I only used part of it, because I couldn't get it all on, and only needed part of it.)

http://www.supermotors.org/getfile/306365/fullsize/timtape.jpg

Go back up top, disconnect the remote starter switch. Reach in with a paint pen or a q-tip or something and paint the end of the pointer. (For reference, at the top of this picture is the bottom of the idler pulley, at the bottom left is the top of the tensioner pulley, and at the bottom right is the top of the water pump pulley.)

Don't loosen it yet, though, we need to warm up the engine. Put everything back on that you took off (neg battery cable, coil wire, intake tube), and fire it up. Let it get up to normal operating temperatures. Wait for the thermostat to open (when the top radiator hose goes hot). Shut it down.

Find your SPOUT connector. Here's mine, the light gray thing in the red circle. That thing above it is the cruise control servo. It's in the rear driverside corner of the engine compartment. Just unlatch the latches, pull the gray tab out of the connector, and put it somewhere safe.

And here's the signal pickup clamped around the #1 wire:

Watch your wires so they don't get into the fan or belt. Point the timing light at the timing pointer, start up the engine, and the strobe light in the timing light will fire every time the #1 cylinder fires, "freezing" the view in place so that you can read the timing setting. (You'd be amazed how hard it was to get this shot with an auto-focusing digital camera.)

http://www.supermotors.org/getfile/306362/fullsize/timing.jpg

Shut down the engine. Loosen the distributor clamp bolt that we discussed earlier, just enough that it allows the distributor to turn. Rotate the distributor (just grab it by the cap and turn it) clockwise to advance the timing (advance means go further BTDC, so 11 BTDC is 1 degree advanced from 10 BTDC). You're shooting for about 13 or 13.5 degrees. The picture above shows 13 degrees.

Start up again and check the timing. Shut down and tighten the clamp bolt back down when you've got the timing where you want it. Here you can see how little we actually turned the distributor (small white mark used to be under the clamp bolt).

The bolt doesn't have to be super tight, just enough so that the timing doesn't change on its own and the bolt doesn't loosen on its own.

Put the SPOUT connector back in. Check all your connections and make sure that you have re-attached everything you detached.

Take it out for a spin. Hopefully your mileage and performance will both be improved. If you hear any "pinging" (a rattling sound from the engine), especially during acceleration, you may have advanced the timing too far. Back it off a little.

http://www.supermotors.net/registry/11474/32259

Last edited by a moderator:

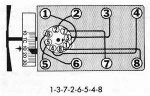

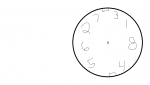

in a previous forum entitled plugwires/plug layout to distributor, it shows the firing order of 1 5 4 2 6 3 7 8 but doesn't specify if it is a 302 or a 351 for the years of 87-93. I have a 1992 bronco with a 351 and had been using the firing order of 1 3 7 2 6 5 4 8.Is this incorrect because if it is, this is the reason that I don't have any power on acceleration.Let me know.

Rons beast

Active member

- Joined

- Dec 13, 2007

- Messages

- 1,537

- Reaction score

- 14

Well gents, thanks to all for helping me get this bronco running again, I guess these gt40 heads I put on here pack some power because after I got the truck timed correctly, I was headed to the highway for a test drive but before I got there I put my foot into it and sheared off the bolts at transfer case.But all is good.Thanks again everybody for the help.

yo Rpg,

That is way too bad after all the work, time & $$ you put in;

did the Bronco run better w/new timing?

That is way too bad after all the work, time & $$ you put in;

did the Bronco run better w/new timing?

yo Rog,

Your Ford dealer may still have some; or get some from a yard queen

look @ this by Ford

same as for your year

See Specs @http://www.diesel-dave.com/vehic/manual/stj/stj51012.htm

Double Cardan (Bronco) Rear Driveshaft-to-Transfer Case Bolts M12-1.75 x 27

Torque to 61-87 ft-lbs

12mm diameter

1.75mm thread pitch (1.75mm between each thread -- think of it as "thread spacing...

27mm length (about an inch long)

Not sure most hardware stores will carry that, but a Fastenal or someplace would

This is by Keith (TTB BLOWS) "...Many newer Broncos have a ****** at the t-case (or rear pinion). The bolts will most likely require a 12pt 12mm wrench. This a cheap one from Autozone that I cut off so I could slip a cheater over it ,,"

click next to see more info & pics

http://www.supermotors.net/clubs/superford/registry/139/13249

Your Ford dealer may still have some; or get some from a yard queen

look @ this by Ford

same as for your year

See Specs @http://www.diesel-dave.com/vehic/manual/stj/stj51012.htm

Double Cardan (Bronco) Rear Driveshaft-to-Transfer Case Bolts M12-1.75 x 27

Torque to 61-87 ft-lbs

12mm diameter

1.75mm thread pitch (1.75mm between each thread -- think of it as "thread spacing...

27mm length (about an inch long)

Not sure most hardware stores will carry that, but a Fastenal or someplace would

This is by Keith (TTB BLOWS) "...Many newer Broncos have a ****** at the t-case (or rear pinion). The bolts will most likely require a 12pt 12mm wrench. This a cheap one from Autozone that I cut off so I could slip a cheater over it ,,"

click next to see more info & pics

http://www.supermotors.net/clubs/superford/registry/139/13249

Last edited by a moderator:

Similar threads

- Replies

- 3

- Views

- 1K

Latest posts

-

-

-

-

OBS Ford Bronco Godzilla Swap Part 3. (Small fire)

- Latest: Broncosandpartsgarage

-