Thanks all. Regarding the coil - I'll do my best to redescribe what's happening, as I'm not sure it was clear.

(In the run position, and...) When both the positive and negative leads are attached to the coil, and i measure voltage from point to point on the coil I only read 5.6v (across the coil). (It remained 5.6v when engine cranked as well.) When i detach the positive (battery) lead from the coil and measure from the lead to the battery or block I read the same voltage as the battery. In essence the coil is dropping voltage by 50%. Is this what is supposed to be happening?

I also tested the resistance of the existing coil and it's at ~1.2 ohms. As a test, i went and picked up a new coil and it measures the exact same way in all settings.

Now, on to the end of the day. Since I was able to get it to fire earlier today with starting fluid, I went ahead and reconnected fuel to carb and removed the crimp from the line pre-pump. I was able to reproduce the issue that I outlined in my OP. Not only can I get it to fire, but I can get it to (barely) run with my foot buried. Eventually, it dies however. (And it will die immediately if I let off of the pedal at any point.) I took a couple of (YouTube) videos of this for reference:

Cold Start 1

Cold Start 2

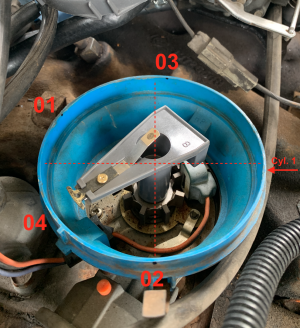

I ran out of daylight so didn't get a chance to further investigate the rotor relative to crank, will do this tomorrow. Would love everyone's further thoughts here!!!

Thanks all for the big help.