Yo,

AFTER SPENDING a LONG TIME ON THIS, AN ERROR MESSAGE STOPPED ME FROM POSTING BECAUSE I had MORE THAN 10K CHARACTERS!

173 - Oxygen sensor not switching – system is or was rich – Single, Right or Rear HO2S – Fuel control

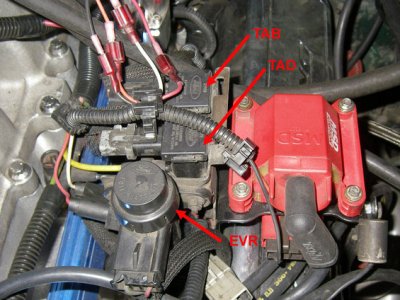

DTC 41, 42, 91, 92, 136, 137,139, 144, 171, 172, 173, 175, 176, 177 & some Possible Causes for Rich & Lean HEGO The engine temperature must be greater than 50°F (10°C) to pass the KOEO Self-Test and greater than 180°F (82°C) to pass the KOER Self-Test. To accomplish this, the engine should be at normal operating temperature Source: by Ryan M (Fireguy50)

For now, ignore tsbs as you have inspected harness...

DTC 172, 173 or 41 for HO2S Failure, in POSSIBLE LOCATIONS OF WIRING SHORTS TSB 95-02-11 for 92-95 Bronco & F Series; "the HO2S wires in the 12A690 (subassembly of the 14B060 battery cable) harness may be cut on the lower right engine mount causing improper signals to be sent to the PCM. Damage may be under the electrical tape..."

DTC 172, 173 or 41 for HO2S Failure Or Fuse \"E\" Inoperative, ABS Light On, Back-Up Lamps Inoperative, Daytime Running Lamp (DRL) Inoperative, MIL On, Inadvertent Self-Test, Speedometer Inoperative & Trailer Battery Charge Relay Inoperative in TSB 95-5-21 for 92-95 Bronco & F Series; "...the HO2S wires in the 12A690 (subassembly of the 14B060 battery cable) harness may become chafed and the vehicle could exhibit any one of the following conditions....Lack of proper HEGO operation may cause, or be the result of a rich or lean fuel condition, which could cause additional heat in the catalyst. Perform self test KOEO and KOER, service any codes. CHECK FOR PROPER HEGO GROUND. If the HEGO ground is good, the following areas may be at fault: ..." READ MORE

Source: by Ford via Steve83 (Steve, That dirty old truck) 1983 Ford Bronco TSBs & FSAs (Recalls) for '83-96 Broncos & F150s picture | SuperMotors.net

DTC 173 Oxygen sensor not switching - system is or was rich - Single, Right or Rear HO2S; "...I'd guess there's either an obstruction in the exhaust pipe directing the exhaust away from it, preventing it from detecting & operating normally (not likely), OR there may be a fault in the heating element circuit (more likely). It comes off the circuit (can't remember which fuse) which also feed A LOT of other things and runs around the front of the radiator to the R side near the battery where it drops down by the engine mount & goes to the sensor. Make sure you have good power & ground to the appropriate terminals in the connector, and test for a signal voltage. Then, using the old & the new sensors, trace the fault..."

Source: by Steve83

DTC 173 in 94 by Ford

Fuel Control

Excerpts...1994 PCED OBDI-A

SECTION 6A: EEC-IV Pinpoint Test

Procedures

H: Fuel Control

H: Introduction

H1 CHECK FOR FUEL DILUTED ENGINE OIL

Diagnostic Trouble Code (DTC) HO2S Orientation Fault Definition

172r

136r

176c right or rear

left or front

left or front system indicates lean

173r

137r

177c right or rear

left or front

left or front system indicates rich

144c

139c right or rear

left or front no HO2S switch

detected

171c

175c right or rear

left or front adaptive fuel limit

reached

Possible Causes:

Fuel injectors.

HO2S.

Secondary Air Injection (AIR) system.

PCV/Hose.

Vacuum.

CANP.

MAP sensor.

Electronic Ignition Coil Failure.

Key off.

Remove the PCV valve from the valve cover. Inspect both rocker cover hole and PCV for damage, sludge build up, blockage and movement of valve plunger. Service as necessary.

Run Key On Engine Off (KOEO) and Key On Engine Running (KOER) Self-Tests.

Address any continuous ignition DTCs before servicing KOER DTCs.

Note: For a No Start, GO directly to H2.

Are any of the above DTCs present in KOER Self-Test?

Yes

REINSTALL PCV valve. GO to H2.

No For Continuous Memory DTCs 139, 144, 171, 176,177 GO to H2

All Others:

CHANGE engine oil and filter. REINSTALL PCV valve

...

skipping to ..

H14 CHECK HO2S INTEGRITY

HO2S always lean, slow to switch or lack of switching. Fuel at adaptive limit could be caused by:

Moisture inside the HO2S harness connector resulting in a short to ground.

HO2S coated with contaminants.

HO2S circuit open.

HO2S circuit shorted to ground.

Key off.

Inspect the HO2S harness for chafing, burns or other indications of damage. Service as necessary.

Inspect HO2S and connector for indication of submerging in water, oil, coolant, etc. Service as necessary.

Run engine at 2000 rpm for two minutes.

Key off.

Run Engine Running Self-Test.

Skipping to...

Key off.

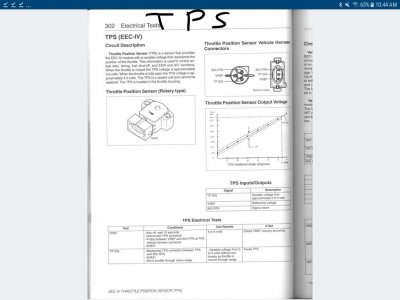

Verify MAP sensor output voltage (refer to procedure in Pinpoint Test Step DF3).

Disconnect appropriate HO2S from vehicle harness.

For 4 wire HO2S (refer to schematic):

Connect DVOM to HO2S circuit and HO2S GND or SIG RTN at the HO2S connector.

Skipping to

H24 CHECK HO2S SIGNAL FOR SHORT TO POWER

With dual HO2S, DTC 173 refers to right or rear HO2S; DTCs 137 and 177 refer to left or front HO2S.

HO2S always rich could be caused by:

Moisture inside HO2S harness connector resulting in a short to power.

HO2S circuit shorted to power.

Key off.

Disconnect the suspect HO2S from vehicle harness.

Inspect both ends of the connector for damaged or pushed out pins, moisture, corrosion, loose wires, etc. Service as necessary.

Key on, engine off.

Measure voltage between HO2S circuit and PWR GND at the HO2S vehicle harness connector (refer to schematic).

Is voltage less than 0.5 volt?

Mass Air EFI (Sequential Firing) Overview; "...A mass air sensor directly reads the mass of air (or number of molecules of air). By doing this, it can detect the changes in the volume of air, in addition to it's pressure and temperature. Mass air EFI is usually what is called SEFI (Sequential Electronic Fuel Injection), which has one separate wire for each injector and fires them twice for every power stroke of the engine. This makes the injector timing more accurate and will help emissions along with power..."

You have Speed Density EFI Overview; "...In 1986, Ford switched to EFI on 5.0 Bronco engines. 1987 brought the first EFI 5.8. The EFI Ford used for almost all Broncos is what is called speed density. Speed density EFI uses a manifold absolute pressure sensor (MAP), a throttle position sensor (TPS), an air intake temperature sender (ACT) , and the knowledge of the factory intake/exhaust tract which gives your engine certain volumetric efficiencies over it's RPM range. This allows the EEC-IV (Electronic Engine Control IV) to determine the mass (different than volume) of air coming into your engine, and hence the amount of fuel needed to go with this air. Speed density EFI also uses what is called bank fire injection. 4 injector are fired at one time on each side of the engine (only 2 wires for firing injectors from EEC-IV)...."

Bank Fire & Sequential Firing Overview; miesk5 Note' "... Speed density EFI also uses what is called bank fire injection. 4 injector are fired at one time on each side of the engine (only 2 wires for firing injectors from EEC-IV)...."

Read much more

This set of tests includes use of Ford's old Break-Out Box; so, as I mentioned in another thread here; In place of the break-out box, go to the EEC connector pin instead; Substitute EEC connector pin Number for breakout box number

EEC IV Connector Pin Diagram

Source: by Fireguy50 (Ryan M) at

EEC IV Connector Pin LEGEND Bronco & Ford Truck & Van: 4.9, 460, 5.0, 5.8;

Source: by Ryan M (Fireguy50) at

http://web.archive.org/web/20120118104425/http://www.oldfuelinjection.com/truckpinouts.html

Also may need to use a parts store's loan-a-tool program for;

Hand held fuel pressure gauge kit

Vacuum gauge

Tachometer

DVOM

Non-powered 12 volt test lamp

See my Vacuum leak test in post #11 @

https://www.fullsizebronco.com/foru...ame-free-zone/206824-help-dtc-codes-idle.html

Excerpts;

One way to do a quick check is to grab a vacuum gauge. Some parts stores will loan you a gauge with refundable deposit.

The vacuum gauge should read between 15 and 22 in-Hg depending upon the engine condition and the altitude at which the test is performed. SUBTRACT ONE INCH FROM THE SPECIFIED READING FOR EVERY 1,000 FEET OF ELEVATION ABOVE SEA LEVEL.

The reading should be quite steady. .

When engine is rapidly accelerated (dotted needle), needle will drop to a low (not to zero) reading. When throttle is suddenly released, the needle will snap back up to a higher than normal figure.

When vacuum leaks are indicated, search out and correct the condition. Excess air leaking into the system will upset the fuel mixture and cause conditions such as rough idle, missing on acceleration, or burned valves. If the leak exists in an accessory unit, such as the power brake, the unit will not function correctly.

Or Air Conditioning when in MAX mode may switch to Defrost.

●