What a great idea! It had probably been 10 years since my last one, but I recently had to wrestle with an older Econoline dual pump setup. I'm going to totally go this route next one (which just might be that Econoline)

Did you just hang a higher output pump on the existing carrier? Or did you go with an entirely different assembly?

Any tips you could provide would be most appreciated. If you don't want to bugger up this thread, feel free to shoot me a private message.

Or maybe even start an informational threat about it?

Back in the early days (for me) we had problems and kept flow testing pumps, flow test hot, flow test cold. Seems like you put a new pump in today and next week it will fail flow test. We tried everything. FPRs, that stupid canister thing under the truck. Injectors. Nothing made a difference, but fuel flow the only thing that was always borderline.

I don't remember all the specs now, but I was thinking for the Ford 460 it was around 130 liters per hour flow. (around 30 gallons per hour) (could totally be off there)

So we were buying 155lph pumps from Summit racing, Just generic high pressure fuel pump.

At first went all out. Soldered a new pipe to the existing hanger to help support the weight of the pump.

After we did a few of them, now we just hose clamp the new pump on and leave it. Seems to be holding up just fine. We have a motorhome here that has been running 12 years now that way. They work it hard too, pulling trailers with it.

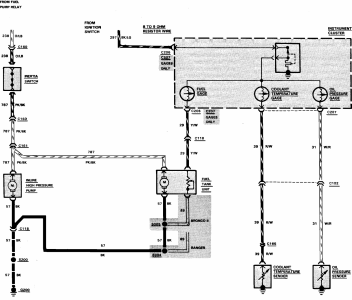

At that time you could get metal fuel line repair pieces from the help section at parts store. We used that to bypass the frame rail pump. Quick, fast, and easy.

Just plugs right in. No effort required.

Then you can see the pics below. You spend most of your time setting the depth of the new pump. After that splice the harness, then plug and play.