Yo Zack,

Welcome!

Following is what a mechanic would check. Try to do as much as you can yourself.

Feel free to ask more questions.

For slow cranking:Inspect for loose battery posts, connectors, cables and visible wire strands & under insulation an inch or so under coonectors:- inspect for corrosion, damage or looseness.- include ground cables from battery post & connector to engine, frame, intake manifold, hood, etc.;- and positive cable from battery to relay to starter.- check starter relay body to inner fender for tightness to a clean, non-rusted/grime -free surface.- check battery for full charge; Voltage; "...a normal battery that is fully charged produces 12.6 volts, not just 12.0 V.

by El Kabong "Cheesy clamp on end. Do not use for a long term repair. Only to get you home when nothing else is available. If you have one of these, suspect it before anything else" El Kabong @

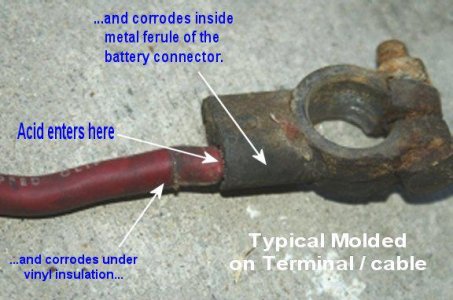

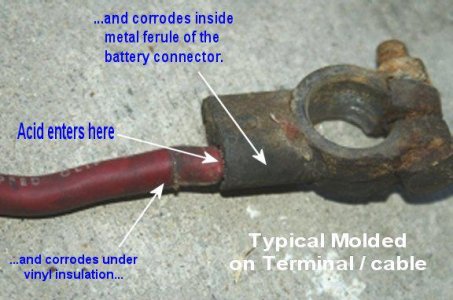

https://www.fullsizebronco.com/forum...lies-faqs.html- use the red and black battery anti-corrosion felt "washers".Slow Cranking or a Grinding Noise; "... Problems with the negative battery cable is a major cause of starting problems in Ford, Lincoln, and Mercury vehicles. Bad battery cables can cause slow cranking or a grinding noise when trying to start an engine. On some late model vehicles, the wire connection inside the battery terminal connector corrodes easily.

miesk5 note, look for greenish corrosion under insulation neat the connector.This will cause a voltage drop in the cable and result in low voltage being supplied to the starter. You can check for voltage drop in the cable using a digital voltmeter. Connect the negative probe of the voltmeter to the negative battery post (not the battery terminal connector). Then connect the positive probe to the starter case and crank the engine. The voltage reading should be less than .5 volts. A higher reading means there is resistance in the cable or the battery terminal connector. Clean the cable end and the battery terminal connector and test again. If the voltage reading is still higher than .5 volts, replace the cable and the battery terminal connector..."Source: by genco1.com"...Why are the cables and battery so important? The starter circuit pulls a lot of amperage, up to 500 amps depending on the starter, the engine load, and battery condition. This kind of amperage stresses all of the components in the starter circuit, including the battery, battery terminals, the cables including the

ground path. Problems with these components are hard to find because they appear fine at rest or under a light load, but generate high resistance under heavy amperage draws. The result will be low voltage to the starter during cranking, resulting in heavier amperage draw and increased internal heat in the starter. Over time, this will cause starter failure. Voltage measured at the starter during cranking should always be above 9.5VDC..."Source: by powermastermotorsportsIf all passes, pull starter for a free starter no-load test @ local parts store.

●

Shuts Off While Driving:

Try a

Self Test for Diagnostic Trouble Codes (DTC)s by my pal, BroncoJoe19Post Code(s) here according to:KOEO & KOERA helper can assist you by counting the codes. Some use their smart phones to record them.BEWARE OF FAN, BELTS, PULLEYS, HOT HOSES, IGNITION HIGH TENSION WIRES, AND ENGINE COMPONENTSOr ask local mom and dad parts stores if they will test it for you. The majority of parts chain stores tests just OBDII vehicles now.Or purchase a coder reader such as;"Innova ODB-1 and we generally recommend getting the extension cord with it, so you can work the ignition key in the cab while watching/holding the reader. It will save the codes but knowing when to go through the cycles and ensuring you get it right the first time can save time and hassle, especially if you're working on it by yourself, as most of us do." by BikerPepe`.

Some Code for now;

DTC 14 & 18; If the distributor mounted Thick FiIm Ignition Module is failing from heat, it can give off computer codes 14 (PIP) and 18 (SPOUT). Stalling or sputtering when, hot but runs when it cools off can be caused by a faulty Module and the biggest culprits are heat. Another culprit can be a wire grounding out.

- Stall, NO Start - This bulletin addresses loss of module ground due to salt and moisture entering a module mounting *****.

- NO Start/Stall at Idle - New Ignition Module: This TSB talks about an internal short-circuit in some model TFI modules.

- Driveability Concerns - Moist EEC-IV Connectors: This bulletin asks the tech to check for unsealed EEC-IV connectors and check for moisture or corrosion.

Wiring:

Always check your wiring. Here is a picture of SPOUT (Spark Output signal) wire that was grounding out.

The yellow spark output signal wire is without a section of insulation. This section happens to run through a shield ground that provided a convenient ground source for the SPOUT signal. Just the right bump in the road or vibration from the engine would provide a path of lesser resistance for the SPOUT signal, killing the coil trigger.

SPOUT Connector pic in an 88 5.0

by jem270

BTW, the SPOUT connector is pulled out when timing the engine.

...

This is where the TFI Modile plugs in to the distributor to get the PIP signal. Notice the defective insulation.

Heat Is Your Enemy!:

The top three leads (for PIP signal) can lose continuity with the back plate (ground) on the module when the unit is hot. You should consider a

remote mounted TFI.

Ignition Control Module (ICM) L

ocation pic @ distributor in an 89

it's the rectangular object with wires on right side.

Source: by Handy_andy_cv64 (Ed )

Take your ignition module off and have it tested. Have them test it up to three times. If it fails any one of those times, replace it. It is located on.

Ignition Control Module (ICM) Removal Tips @ distributor; "...To remove the TFI = thick film integrated module you need to loosen the saftey "lock bolt" at base of the distributor so you can TURN the distributor for better access and removal but make a referecne mark so you can turn the distributor back exactly where it was otherwise you'll have to re-set the timimg so it will start and run properly. There's a special tool "ignition module socket, mfg by Powerbuilt # 648420 so you can remove the screws on the module to replace it BUT to test it you just need to turn the ignition key to the "RUN" position, engine off. don't remember what I paid for the "socket" maybe $15.00 range...?Source: by our late friend, JKossarides ("The Bronco", Jean)

Go through this guide;

Part 1 -How to Troubleshoot a No Start (Ford 4.9L, 5.0L, 5.8L).How To Test The Ford Ignition Control Module (Distributor Mounted) @

https://easyautodiagnostics.com/ford/4.9L-5.0L-5.8L/ignition-control-module-tests-1

●Some other Stalls When Hot Tests without a Code:

"Long crank times may be traced to a sticking Idle Air Control (IAC) valve (TSB 97-9-5, April '97); "...After a 1-4 hour engine soak time, long crank times and/or long crank to start followed by a stall may occur on some vehicles. No further stalling or rough idle will occur after the engine is running. The long crank and/or stall may be due to the Idle Air Control (IAC) Valve sticking. Replace the IAC Valve with a revised IAC Valve if no Diagnostic Trouble Codes (DTCs) are present."

●

"Unplug the MAP sensor on the passenger side firewall and see if it starts. If it starts, you have a bad MAP sensor. Typically the computer will throw a MAP communication code for that one though".by Lil' RedMAP Location pic

by Richard C (Bigric, Money Pit)¤Unplug/test the IAC by SeattleFSB @

https://www.fullsizebronco.com/forum...-your-iac.html

●Some no code usual suspects by Ford;Vacuum Leak;

"One way to do a quick check is to grab a vacuum gauge. Some parts stores will loan you a gauge with refundable deposit.The vacuum gauge should read between 15 and 22 in-Hg depending upon the engine condition and the altitude at which the test is performed. SUBTRACT ONE INCH FROM THE SPECIFIED READING FOR EVERY 1,000 FEET OF ELEVATION ABOVE SEA LEVEL.The reading should be quite steady. .When engine is rapidly accelerated (dotted needle), needle will drop to a low (not to zero) reading. When throttle is suddenly released, the needle will snap back up to a higher than normal figure.When vacuum leaks are indicated, search out and correct the condition. Excess air leaking into the system will upset the fuel mixture and cause conditions such as rough idle, missing on acceleration, or burned valves. If the leak exists in an accessory unit, such as the power brake, the unit will not function correctly.

Or Air Conditioning when in MAX mode may switch to Defrost."see my leak diagnosis link in post #11 @

https://www.fullsizebronco.com/forum...odes-idle.htmlAir filter, is it relatively clean?Air inlet atop radiator support to filter box and to throttle body; look for obstruction; damaged tubing, openings in tubing, loose fit at throttle body or if at MAF sensor.Fuel quality; Oxidized fuel often turns darker over time and may even smell sour. You can check stored gasoline by pouring some into a clear glass container and comparing it side-by-side with known fresh gasoline. If your old sample looks noticeably darker than the fresh gas, you have strong evidence the gas has gone bad.Electrical connectors; inspect for corrosion, etc at coil, firewall, ICM, distributor, PCM, etc. especially those with broken locking tabs.

GL! Al