yo,

The PIP wire insul. thAng could give DTC 211 as described in;

TSB 95-15-11 Hesitation, Stumble, Stall, Miss, No Start, No Spark by Ford via Chilton

HESITATION/STUMBLE—INTERMITTENT—4.9L, 5.0L, 5.8L AND 7.5L ENGINES

MISS—INTERMITTENT—4.9L, 5.0L, 5.8L AND 7.5L ENGINES

NO START/NO SPARK—INTERMITTENT—4.9L, 5.0L, 5.8L AND 7.5L ENGINES

STALL—INTERMITTENT—4.9L, 5.0L, 5.8L AND 7.5L ENGINES

ISSUE:

Vehicles may exhibit various driveability symptoms, such as no start, no spark, hesitation/stumble/stall/miss and/or Diagnostic Trouble Code (DTC) 211. The symptoms may occur during any drive mode or at idle. These concerns may be caused by the shielding drain wire (Circuit 48.) cutting through the insulation of, and shorting to, the Profile Ignition Pickup (PIP) wire (Circuit 395) or the spark output (SPOUT) wire (Circuit 929) near the Powertrain Control Module (PCM) 60-pin connector. A protruding wire from Splice 145 may also cause the same concern as the wire strand shorts to the PIP, SPOUT, or the foil wrap surrounding the drain wire.

ACTION:

Inspect PIP - Circuit 395 (GY/O), Ignition Ground (IGN GND) - Circuit 259 (O/R), and SPOUT - Circuit 929 (PK) for possible cut insulation from Circuit 48. Also, inspect Splice 145 - Circuit 395 (GY/O) for stray wire strands. If wire insulation is cut, exposing copper wire, repair cut insulation with 3M Mastic Tape. Refer to the following procedure for service details.

SERVICE PROCEDURE

1. Disconnect battery ground cable.

2. If vehicle has the speed control option, remove the speed control servo bracket and position it out of the way for improved access.

3. Disconnect the connector at the Ignition Control Module (ICM - formerly TFI).

4. Unbolt the 60-pin connector from the PCM and pull the wiring up to work on.

5. Remove the 1" (25.4mm) diameter convoluted tubing from the wiring assembly. The date code tag will remain taped to the convoluted tubing.

6. Remove/cut the tape of the wiring assembly. Work toward the the ICM connector (pull back convoluted tubing as needed).

7. Unravel aluminum foil tape and electrical drain wire (Circuit 48.) from main bundle, exposing the junction or "Y" splice between the ICM tapeout and the PCM tapeout. Be careful with the foil wrap because it will be reused.

NOTE: THE FOIL WRAP LENGTH WILL BE ABOUT 5" (127mm) BEYOND THE "Y" BRANCH. THE END WILL BE TOWARD THE ICM CONNECTOR.

8. After the foil wrap is removed, look for the three (3) "grouped" wires in question at the "Y" splice. The three (3) wires are: PIP - Circuit 395 (GY/O), IGN GND - Circuit 259 (O/R), and SPOUT - Circuit 929 (PK).

9. Locate the (bare) electrical drain wire. Wire end is toward the ICM connector, again, about 5" (127mm) from the "Y" splice. Unravel wire from the top (ICM) end and down to the area where the bare wire makes contact with the three (3) wires mentioned above.

10. Inspect for any damage to the insulation of the three (3) wires in question. If wire insulation is cut, exposing copper wire, repair cut insulation with 3M Electrical Moisture Sealant-Mastic Tape (3M Part No. 054007-06147).

11. Inspect Splice 145 - Circuit 395 (GY/O) for stray wire strands (Figure 3). If stray wire is found, apply pressure on the wire with pliers to bend the wire down and wrap the splice with three (3) layers of flame retardant vinyl tape, or equivalent, to ensure the wire does not make contact with other wires or the foil wrap.

12. Carefully rewrap the bare electrical drain wire and foil. Work backward, toward the ICM connector end. Tape end of foil wrap to secure.

13. Retape worked area securely (between PCM and ICM connectors) with flame retardant vinyl tape, or equivalent.

14. Reinstall all convoluted tubing and tape ends of tubing to the tubing with flame retardant vinyl tape, or equivalent.

15. Reinstall PCM connector to the PCM.

16. Reinstall the ICM connector.

17. Reinstall the speed control servo bracket (two bolts) if applicable, and tighten bolts to 15-18 N-m (11-13 lb-ft).

18. Reconnect battery ground cable.

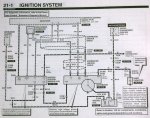

SEE DIAGRAMS