I'll add my 4 cents.

If it's an R12 system converted to R134, they will never blow as cold as the old R12, especially in hot and HUMID climates.

R134 also operates best a lower pressures. Example: R12 will blow coldest around 32-34 psi on the low side. and the system risks icing up if pressure drops too low. So Ford, like all others who do not use an expansion valve, incorporates a low-pressure cycling switch calibrated to turn off the AC compressor clutch when low side drops below 28-29 psi. With a healthy system, at idle you would hear your AC compressor shutting off for maybe 5 second intervals every 15-30 seconds while maintaining a nippy 38* F output temp inside your cab.

With R134 though, that's not low enough. It operates most effectively at around 26-28 low side psi, so just as it starts to cool down some, that darned switch kicks it off like some cruel edging, and you end up with more frequent clutch cycling and a balmy 58* outlet temp.

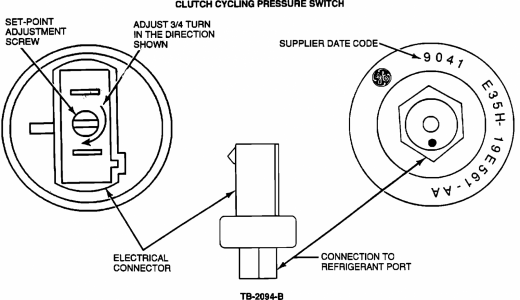

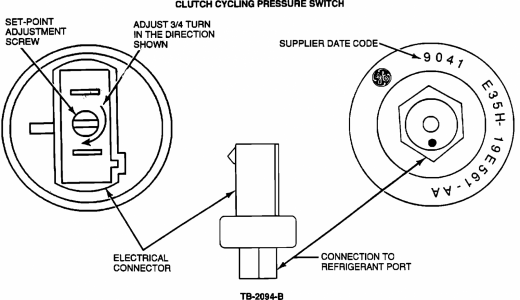

Lucky for us--and not all techs are aware of this, even seasoned ones, and you'll not find this in Ford service data back in R12 days--but Ford's cycling switches are adjustable!

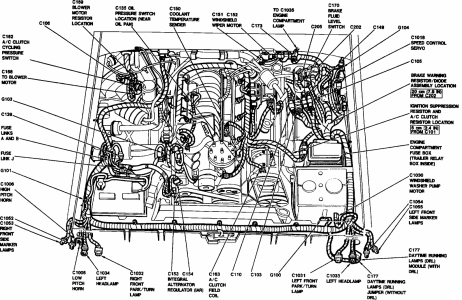

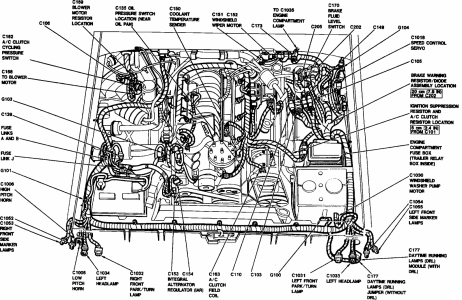

This switch lives on the accumulator, or receiver dryer at about 10:00 in the photo here.

Ford did issue a recalibrated cycling switch right around your vintage for switch calibrations that drifted downward, causing overheated evaporators and chemical metallic odors in the cab. They recommended either adjusting your existing switch a quarter-turn in to increase the cycling pressure and allow more frequent cycling, or replace with the updated unit.

You're going to want to go the opposite direction of curse. Ideally, having a pressure gauge attached to the low pressure side is best, wherein you would adjust until your compressor is cycled off around 24-26 psi. However, it's not totally necessary, and a quarter turn counter-clockwise should do the trick.

You'll know you've gone too far if your compressor no longer cycles off and the pipe coming off your accumulator start to freeze. Simply rotate the adjuster in just a smidge back at a time until you find that happy place of no icing and your cycling ratio of about 5 second intervals off for every 15-30 seconds on.

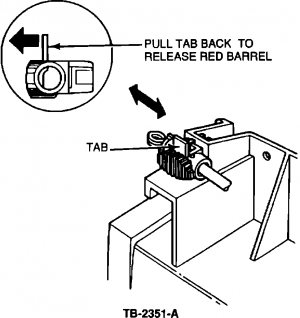

Here's a shot of that switch looking into where the connector attaches:

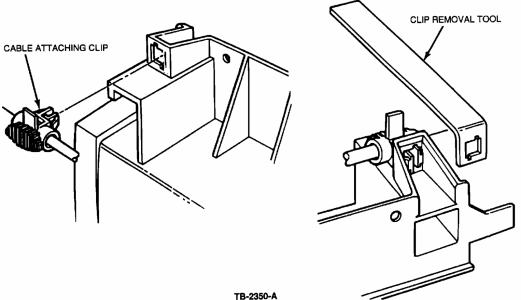

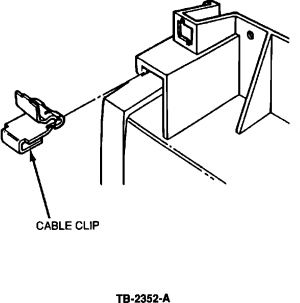

You can twist them off by hand if you can't get a screwdriver in there. They are spun onto a shroeder valve, so you'll lose no refrigerant.

If it still is not cool enough, and you are confident there is the proper amount of refrigerant in there...

Wait, that's an item too. Your system capacity is 44 oz of R12, but R134 operates on less refrigerant, and hopefully this shop is well versed. (I have no doubt in Fla) Just in case though, look at your invoice. At 75-85% less R134 required, you should have been billed for 33 to 37 oz max, or 2.1 to 2.5 lbs. If they billed you for any higher than 37 oz, or 2.75 to 3 lbs, that's too much, and it won't get cool.

Anyway, where was I? Oh yes...

If it still is not cool enough, and you are confident there is the proper amount of refrigerant in there, there are a few TSBs covering this issue beyond my cycling switch novel up there. I've pasted the bodies of a couple of them in my next post. (this one is too big to post, oops)