Hay chaps.

today i managed to snap one of my axles rigth next to the splines in the carrier and i also found a crack in the thirdmember housing.

so im wondering if the following whoud be possible as a "emergency suloution while i wait for parts:

Whoud the following setup work:

IF i remove the ring gear and driveshaft to the rear wheels. (driving the car in 4wheel drive on the front wheels only)

whoud it be "ok" to drive the car with the snapped axle?

the axle broke in such a way that the end is still inside the carrier, so it wont be "flopping around" in the axle tube

My current setup is a old 28 spline carrier (w minispool) and axles from a mustang, so i plan on buying a new 31 spline carrier, new thirdmember housing, and 31 spline axles.

but i cannot afford it all in one go.

and i live in europe so 9 inch axles are hard to get used parts for. so im gonan be buying my parts new in the us.

so basicly:

is it possible to drive it with the ring gear missing, and the broken axle while i get the new parts?

( i know i cant tow anything go wheeling etc, but if i can get to and from the store il be happy)

or do i atleast have to buy a new 28 spline "shit axle" to be able to temporary move the car safely?

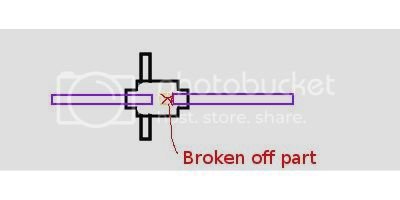

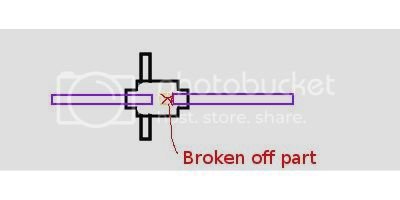

Some pics of the dmg:

today i managed to snap one of my axles rigth next to the splines in the carrier and i also found a crack in the thirdmember housing.

so im wondering if the following whoud be possible as a "emergency suloution while i wait for parts:

Whoud the following setup work:

IF i remove the ring gear and driveshaft to the rear wheels. (driving the car in 4wheel drive on the front wheels only)

whoud it be "ok" to drive the car with the snapped axle?

the axle broke in such a way that the end is still inside the carrier, so it wont be "flopping around" in the axle tube

My current setup is a old 28 spline carrier (w minispool) and axles from a mustang, so i plan on buying a new 31 spline carrier, new thirdmember housing, and 31 spline axles.

but i cannot afford it all in one go.

and i live in europe so 9 inch axles are hard to get used parts for. so im gonan be buying my parts new in the us.

so basicly:

is it possible to drive it with the ring gear missing, and the broken axle while i get the new parts?

( i know i cant tow anything go wheeling etc, but if i can get to and from the store il be happy)

or do i atleast have to buy a new 28 spline "shit axle" to be able to temporary move the car safely?

Some pics of the dmg:

Last edited by a moderator: