I just took the engine (only 6 months old), harness, and ECU from my wrecked 88 bronco and put it in another 88. Everything ran great in the old one but now when I increase the RPMs over 2000 it jumps down 400-500 RPMs and back up again every 15-20 seconds. Over 3000 RPMs and it jumps up 400-500 RPMs and back down every 15-20 seconds. Fuel pressure gage reads 32psi KOEO, 34psi at idle, and stays at 34psi no matter what RPM i increase to. I've changed high pressure fuel pump, fuel filter, FPR, MAP sensor, cap and rotor. Tested the Intake Temp Sensor. I can't pull codes because for some reason my EEC connection does not work and my CE light won't shut off when the key is on. My thought is that something is making the ECU think its running rich and adjusting for it. I'm not sure where to go from here. Thoughts??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

88 Bronco 5.0 surges when RPMs go over 2000

- Thread starter Jbford

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Yo JB,

Welcome!

Too bad about not being able to read codes, if any.

Scan Tool Won't Initiate Self-Test Due to Poor Grounds, Corroded Wiring, etc.; read more on how to Ground the STI & Proceed w/ Test; miesk5 Note; Steve83 advises; "...If the CEL is burned out, connect CEL (C) to a 12V test light, and the light's other terminal to a 12V source on the same vehicle..."

Source: by Jeremy M (Big '92, jermil01)

●

KOEO is a bit low.

●

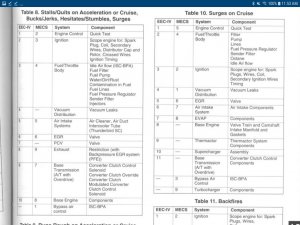

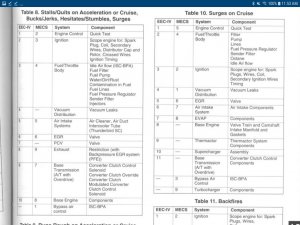

Surge, "QUITS" (RPM "DROP") Look at tables 8 & 10 below;

Pull vacuum hose from fuel pressure regulator; is any fuel or aroma thereof, replace FPR because it's diaphragm is ruptured.

See my Vacuum leak test in post #11 @ https://www.fullsizebronco.com/threads/help-with-dtc-codes-and-idle.206824/

Often, in engine swaps the EGR be loose, or EVP has a vacuum leak.

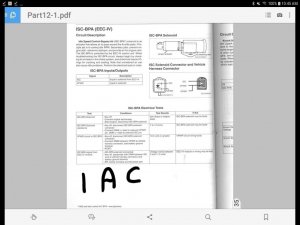

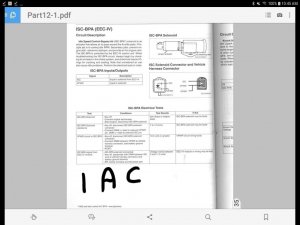

Inspect IAC:

●□●

Here's the 1988 Ford Bronco & Truck Service Manuals by Larry J via Kingfish999 in Google Drive @ 1988 Ford Truck Service Manuals (Thank you Larry Jorgensen) - Google Drive

1988 Bronco Dealer Brochure @ https://www.broncocorral.com/resources/1988_ford_bronco_brochure.pdf

Haynes Red Manual for 80-95 Bronco & F Series @ Hanes guide 80-96 bko f series.pdf by BroncMom

Al

Welcome!

Too bad about not being able to read codes, if any.

Scan Tool Won't Initiate Self-Test Due to Poor Grounds, Corroded Wiring, etc.; read more on how to Ground the STI & Proceed w/ Test; miesk5 Note; Steve83 advises; "...If the CEL is burned out, connect CEL (C) to a 12V test light, and the light's other terminal to a 12V source on the same vehicle..."

Source: by Jeremy M (Big '92, jermil01)

●

KOEO is a bit low.

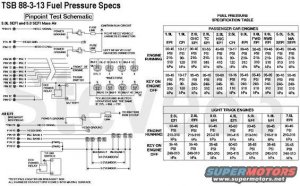

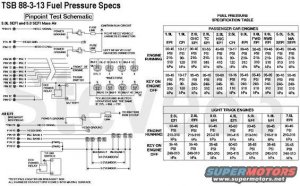

Publication Date: FEBRUARY 2, 1988 FORD: 1988 ******/EXP, MUSTANG, TEMPO, THUNDERBIRD, TAURUS, CROWN VICTORIALINCOLN-MERCURY: 1988 TOPAZ, COUGAR, SABLE, GRAND MARQUIS, MARK VII, CONTINENTAL, LINCOLN TOWN CAR LIGHT TRUCK: 1988 ALL LIGHT TRUCK LINES ISSUE: The fuel pressure specification ranges for some engine applications are incorrect as published in the 1988 Engine/Emission Diagnosis Manual, Pinpoint Test "H", Section 19, Page 130. ACTION: If service is required, use the fuel pressure specifications from the chart. |

●

Surge, "QUITS" (RPM "DROP") Look at tables 8 & 10 below;

|

See my Vacuum leak test in post #11 @ https://www.fullsizebronco.com/threads/help-with-dtc-codes-and-idle.206824/

Often, in engine swaps the EGR be loose, or EVP has a vacuum leak.

Inspect IAC:

●□●

Here's the 1988 Ford Bronco & Truck Service Manuals by Larry J via Kingfish999 in Google Drive @ 1988 Ford Truck Service Manuals (Thank you Larry Jorgensen) - Google Drive

1988 Bronco Dealer Brochure @ https://www.broncocorral.com/resources/1988_ford_bronco_brochure.pdf

Haynes Red Manual for 80-95 Bronco & F Series @ Hanes guide 80-96 bko f series.pdf by BroncMom

Al

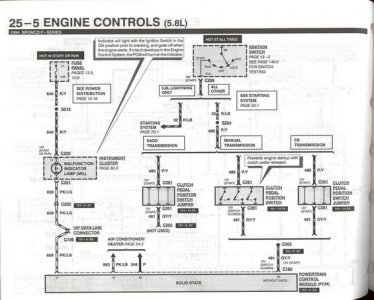

Attachments

Last edited:

Yo,

Sorry, my tablet has an issue causing the mess above

Sorry, my tablet has an issue causing the mess above

Forgot to mention that the fuel pressure holds steady for quite awhile after turning engine off.

I'll try grounding the single pin connector directly to the battery when I get home this evening and I'll post the results.

I'll try grounding the single pin connector directly to the battery when I get home this evening and I'll post the results.

Miesk5, By the time I got home last night I was only able to try connecting the SPI directly to the battery to see if I could get any codes. Unfortunately it still did not work. I think I might try running new wires from EEC test plug to their appropriate locations.

Tiha, below 3000rpm it decreases by 400-500 rpms and when I increase rpms over 3000 then it increases by 400-500 rpms. In either case it does this about every 15-20 seconds and doesn't stop.

Tiha, below 3000rpm it decreases by 400-500 rpms and when I increase rpms over 3000 then it increases by 400-500 rpms. In either case it does this about every 15-20 seconds and doesn't stop.

paul rondelli

Active member

I had a stalling/ sluggish response issue on my 1996. Thought it was spark based so I replaced cap/rotor/plugs/wires/ and coil. Still acted up at full throttle. Finally threw a code .. and i narrowed it down to the PIP sending the ECM bad information. Replaced the dizzy and she runs well. My old dizzy had some resistance while I turned it by hand... the new one turned like butter. I guess the resistance in the old dizzy would generate heat and cause the PIP to malfunction.

Well here's the update........anybody want to buy a Bronco? JK!! Not ready to throw in the towel just yet.

-Today I checked continuity of the wires from the ECM to all the engine sensors and solenoids. All were good.

-Verified continuity of EEC Test plug wires going to the ECM. Blk/white, Pink/L. Grn, and Tan/L. Grn were all good. Those are the only wires I have other than the STI which also tested good.

-I did find the fuselink going to the E Coil was fried. Repaired with new fuselink

- Verified good ground between Battery and Body, Battery and Frame, and Battery and Engine Block

-O2 sensor did not pass test. New one installed

-Tested the EGR Solenoid, it's good.

-EGR holds vacuum

-I found out that the CE light has no power going to it so that explains why I can't pull codes with it. Going to try and run that down on Thursday.

-I disconnected the battery cables for 20 minutes hoping to reset/delete any codes in the ECM.

After all this ..........no improvement.

Any thoughts on where I go from here?

-Today I checked continuity of the wires from the ECM to all the engine sensors and solenoids. All were good.

-Verified continuity of EEC Test plug wires going to the ECM. Blk/white, Pink/L. Grn, and Tan/L. Grn were all good. Those are the only wires I have other than the STI which also tested good.

-I did find the fuselink going to the E Coil was fried. Repaired with new fuselink

- Verified good ground between Battery and Body, Battery and Frame, and Battery and Engine Block

-O2 sensor did not pass test. New one installed

-Tested the EGR Solenoid, it's good.

-EGR holds vacuum

-I found out that the CE light has no power going to it so that explains why I can't pull codes with it. Going to try and run that down on Thursday.

-I disconnected the battery cables for 20 minutes hoping to reset/delete any codes in the ECM.

After all this ..........no improvement.

Any thoughts on where I go from here?

BIG ACE

New member

- Joined

- Sep 23, 2019

- Messages

- 18

- Reaction score

- 19

Hey job, I had the same issue, sounds like your egr valve is shot.

Menesesjesse

New member

- Joined

- Dec 13, 2016

- Messages

- 3

- Reaction score

- 1

What do you get in a vacuum gauge at idle?

Latest update....

-I replaced all the vacuum lines

-I replaced the EGR Valve, Solenoid, and Electronic Sensor

No change. :-(

I did remove the instrument cluster and found the positive lead for the CEL was broken. Repaired it by splicing in a 3/4" piece I cut off the printed circuit of another cluster. I then verified continuity of the positive side of the CEL bulb socket in the cluster to the ECM and that's good. I have good continuity from the negative side of the CEL bulb socket to where to harness plugs into the cluster but nothing beyond that. Does the CEL illuminate when the negative side closes or the positve?

I'm running out of ideas on what to check next...............

-I replaced all the vacuum lines

-I replaced the EGR Valve, Solenoid, and Electronic Sensor

No change. :-(

I did remove the instrument cluster and found the positive lead for the CEL was broken. Repaired it by splicing in a 3/4" piece I cut off the printed circuit of another cluster. I then verified continuity of the positive side of the CEL bulb socket in the cluster to the ECM and that's good. I have good continuity from the negative side of the CEL bulb socket to where to harness plugs into the cluster but nothing beyond that. Does the CEL illuminate when the negative side closes or the positve?

I'm running out of ideas on what to check next...............

paul rondelli

Active member

I just read another thread about a guy having sluggish response..... and again the distributor was to blame. I'm not a fan of having the PIP sensor mounted on the side of the distributor like my 1996. That shaft inside the dizzy spins continually... when they get older … heat starts to build up inside the shaft and the PIP starts sending crazy RPM information to the ICM and ECM causing them to try and self correct. … resulting in stalling/ sluggish response. This did not generate a CEL when mine started to get sluggish at acceleration .. until it got real bad and caused a misfire.

I feel it is electrical... and would recommend /wires/cap/coil and rotor but you already did that. If your still rocking a factory dizzy replacing it won't hurt …. and waiting until failure before replacement is sketchy … the shafts have been know to twist and explode inside the housing .. and that would not be good.

I feel it is electrical... and would recommend /wires/cap/coil and rotor but you already did that. If your still rocking a factory dizzy replacing it won't hurt …. and waiting until failure before replacement is sketchy … the shafts have been know to twist and explode inside the housing .. and that would not be good.

paul rondelli

Active member

These coils tend to fail. I know a guy who drives around with a spare coil because he has no faith in their longevity.Paul, I have not replaced the coil but I guess that a good next step.

Tiha, It's so bad I can't even drive it down the driveway

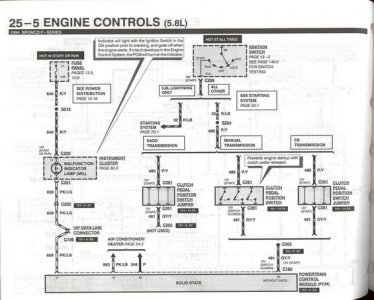

Yo Jbford,

Inspect Fuse #17

Check Engine Light aka Malfunction Indicator Light (MIL) illuminates when EEC provides a ground signal via pin #17.

Inspect pin17 for corrosion, etc.

●

Lastly,

Here are some PCM KILLER perpetrators and other causes:

Smell around the PCM. If it smells like dead fish, it's bad.

Look for PCM printed circuit board burn marks around leaking capacitors, resistors.

For example, see Old leaky capacitors in swapped EEC and no more codes by jowens1126

Water damage from cowl leaks, ESPECIALLY if you you have wet carpet or mat near driver kick panel; or on PCM Connector due to a bad hood seal near cowl panel, viewable with hood up.

Corrosion or damage due to moisture is one of the main reasons for failure. Corrosion can enter through the wiring harness and moisture can enter by a failure in the seals in the PCM itself. This happens over a period of time (5 to 10 years) due to exposure to the elements.

The alternator could be generating an AC voltage spike due to bad diode(s) or supply Voltage Overloads.

I recommend bench-testing the alternator for voltage output and AC voltage ripple.

Thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail.

Bronco was jump started on reverse polarity.

Connector pin damage or corrosion.

Internally PCM killer perps are;

broken tracks,

cold solder joints,

short circuit,

thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail,

Overheated PC,.

Bad Intel 8061 chip or bad Intel 8361 memory chip,

Bad Internal Voltage Regulator, see Wayback Machine by Ryan M

Inspect Fuse #17

Check Engine Light aka Malfunction Indicator Light (MIL) illuminates when EEC provides a ground signal via pin #17.

Inspect pin17 for corrosion, etc.

●

Lastly,

Here are some PCM KILLER perpetrators and other causes:

Smell around the PCM. If it smells like dead fish, it's bad.

Look for PCM printed circuit board burn marks around leaking capacitors, resistors.

For example, see Old leaky capacitors in swapped EEC and no more codes by jowens1126

Water damage from cowl leaks, ESPECIALLY if you you have wet carpet or mat near driver kick panel; or on PCM Connector due to a bad hood seal near cowl panel, viewable with hood up.

Corrosion or damage due to moisture is one of the main reasons for failure. Corrosion can enter through the wiring harness and moisture can enter by a failure in the seals in the PCM itself. This happens over a period of time (5 to 10 years) due to exposure to the elements.

The alternator could be generating an AC voltage spike due to bad diode(s) or supply Voltage Overloads.

I recommend bench-testing the alternator for voltage output and AC voltage ripple.

Thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail.

Bronco was jump started on reverse polarity.

Connector pin damage or corrosion.

Internally PCM killer perps are;

broken tracks,

cold solder joints,

short circuit,

thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail,

Overheated PC,.

Bad Intel 8061 chip or bad Intel 8361 memory chip,

Bad Internal Voltage Regulator, see Wayback Machine by Ryan M

Similar threads

- Replies

- 7

- Views

- 985

- Replies

- 28

- Views

- 5K

Latest posts

-

-

-

-

3 dangers I found out working on my 78 bronco--and maybe yours too

- Latest: 79' Buckin Bronco