Yo Uh,

Finally found this!

"The Fading Bronco Brake Pedal

by Jeff Baskowitz

Vehicles: 1987 through 1998 Ford Bronco. All engines with Rear Anti-lock Braking Systems (RABS).

System: Brakes/ABS.

Symptom/Problem: Brake pedal fade, low pedal. The problem is an internal leak in RABS valve.

Background: A common complaint on Ford light duty trucks with the rear anti-lock brake system is that the brake pedal will fade while under steady pressure. In a conventional brake system this would point to an external fluid leak or an internal leak (bypass) in the master cylinder. Generally, one and usually two master cylinders have been replaced already, leaving one very frustrated technician. In this system there is one other possibility - the rear anti-lock brake valve. This valve is the electro-hydraulic proportioning valve located on the left-hand frame rail between the master cylinder and the rear brakes. This valve controls the brake fluid during an anti-lock stop by restricting or bleeding off rear wheel cylinder pressure.

To better understand what's happening, let's take a quick look at system operation. The RABS module continuously monitors rear wheel speed by means of a sensor installed in the rear differential. When the sensor signal to the module shows a rapid decrease in speed - indicating rear wheel lockup will occur - it energizes the isolation solenoid in the RABS valve. By doing this, the normally open valve is now closed, blocking off the line to prevent further brake fluid from entering the rear wheel cylinders. If there is still too great a decrease in rear wheel speed, the module will then energize the dump solenoid in the RABS valve. This solenoid is normally closed and, when energized, will open a port to the accumulator and bleed off some of the pressure to prevent lockup. This fluid is then stored until normal brake functions are resumed and the fluid is returned to the master cylinder.

If rear wheel speed is now OK, the module de-energizes these solenoids to resume normal braking. If speed decreases too rapidly again, it resumes anti-lock control. The module will alternate between the two solenoids and normal braking until there is no further chance of locking up or vehicle speed is now under 5 mph.

The focus is on this dump portion of the RABS valve. Occasionally the seat between the solenoid and the accumulator will leak, causing the pedal to fade during normal pedal applications. This sinking pedal has no other abnormal braking characteristics and is usually not noticed (depending on severity) unless it sits for an extended amount of time with constant pressure applied. It may be due to physical damage or a buildup of contaminants in the hydraulic system, but the results are the same.

Some customers report that the brakes were just fine until a hydraulic component was replaced or repaired and the brakes were bled. Then the pedal started fading. Quite possibly this is due to a new problem that is created by "moving" some of the contaminated fluid into the valve. To diagnose this system, like all brake systems, first verify that there are no external fluid leaks. If visual inspection is OK, disconnect the brake lines at the master cylinder and plug the outlets in the cylinder. When the master cylinder is plugged, if a fade is still experienced, the master is at fault.

If, however, there is no fade, determine if it is coming from the front or rear brakes by blocking one port at a time at the master cylinder. If there is no longer a fading pedal when blocking the port to the rear line, go one step further and build a short brake line to splice between the inlet and outlet lines at the RABS valve to temporarily bypass the valve.

After bleeding the rear brakes and verifying there is a solid pedal, it's a good bet that the problem is in the valve itself. The next step is to replace and bleed the valve (if equipped with a bleeder) and the rear wheel cylinders. Verify the repair and road test.

Jeff Boskowitz, IDENTIFIX Ford specialist, is certified Ford EEC, MACS, ASE master and L1. He has 26 years of experience."

●

And for future troubleshooting:

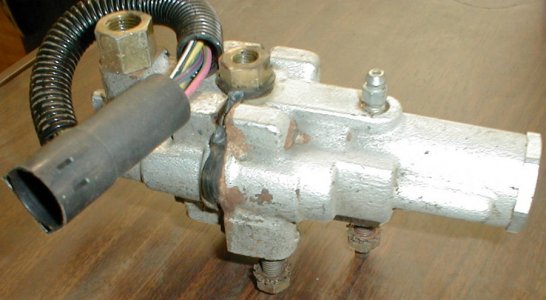

RABS Valve pic in 87-92 Bronco & 87-96 F Series

View attachment 28691

by former member Steve83

Flashout Codes

Whenever the yellow REAR ABS light comes on during normal operation, a flashout code may be obtained to aid in problem diagnosis. If the vehicle is shut off before the code is read from a RABS-I module, the code will be lost. In some cases, the code may reappear when the vehicle is restarted. In other cases, the vehicle may have to be driven to reproduce the problem and, if the problem was associated with an intermittent condition, it may be difficult to reproduce. Therefore, whenever possible, it is recommended that the code be read before the vehicle is shut off.

WARNING: PLACE BLOCKS BEHIND THE REAR WHEELS AND IN FRONT OF THE FRONT WHEELS TO PREVENT THE VEHICLE FROM MOVING WHILE THE FLASHOUT CODE IS BEING TAKEN.

NOTE: If the red BRAKE light is also on, due to a grounding of the fluid level circuit (perhaps low brake fluid), no flashout code will be flashed and the REAR ABS light will remain on steadily.

NOTE: If there is more than one system fault only the first recognized flashout code may be obtained.

WARNING: PLACE BLOCKS BEHIND THE REAR WHEELS AND IN FRONT OF THE FRONT WHEELS TO PREVENT THE VEHICLE FROM MOVING WHILE THE FLASHOUT CODE IS BEING TAKEN.

To obtain the flashout code, locate the RABS diagnostic connector (with the Bk/Or wire), and attach a jumper wire to it. Momentarily ground it to the chassis. When the ground is made and then broken, the REAR ABS light should begin to flash.

NOTE: If the red BRAKE light was on (as noticed before the parking brake was applied), the problem may be with the low fluid level circuit and, in this case, no flashout code will be flashed and the light will remain on steadily.

The code consists of a number of short flashes and ends with a long flash. Count the short flashes and include the following long flash in the count to obtain the code number. For example, three short flashes followed by one long flash indicates Flashout Code Four. The code will continue to repeat itself until the key is turned off. It is recommended that the code be verified by reading it several times. In addition, the first code flashed may be too short because it may have been started in the middle. It should be ignored.

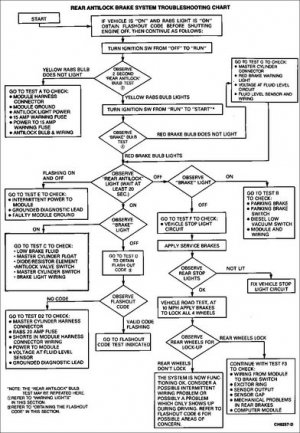

RABS Troubleshooting in 87-88 Broncos @ http://www.supermotors.net/registry/media/559308_1

C

lick NEXT to View more pages; miesk5 Note; for all Resistance tests, battery needs to be disconnected; remove Negative cable at battery

Source: by Jem270

RABS Self Test Diagnostic Connector Location pic in an 88;

View attachment 28693

"...it is next to the brake pedal which this is a picture of and is C111; It has the one wire that is black/orange.."

Source: by Jem270

●

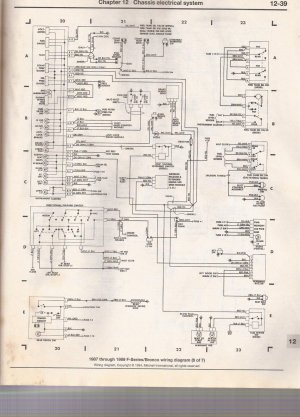

RABS Wiring Diagram in 87-89 Bronco & F series (Mitchell)

View attachment 28692

Source: by equivalent (Beetlejuice) at SuperMotors.net

●

View attachment 28690