Yo Dabbler,

Following by Ford;

"Inspect the cylinder heads for cracks or excessively burned areas in the exhaust outlet ports.

Check the cylinder head for cracks and inspect the gasket surface for burrs and nicks. Small imperfections of this type can be dressed down using an oil stone. Replace the cylinder head if it is cracked.

The following inspection procedures are for a cylinder head that is to be completely overhauled. For individual repair operations, use only the pertinent inspection procedure.

When a cylinder head is removed because of gasket leaks, check the flatness of the cylinder head gasket surface for conformance to specification.

Gasket Removal TSB 93-23-14 for 88-93 Bronco, F Series, Aerostar, Econoline & many others @

"

ISSUE: Some engine assemblies replaced under warranty have been found to be internally contaminated. This condition may be traceable to a previous repair involving removal of the valve cover(s), intake manifold and cylinder head(s). Scuffed pistons/bores, excessively worn crankshaft/camshaft bearings, low or no oil pressure, engine knocking and excessive oil consumption can result from improper engine gasket surface preparation.

ACTION: Refer to the following TSB article for gasket sealing surface preparation procedures recommended by Ford Motor Company.

SERVICE PROCEDURE

1. Identify the composition of the component part before proceeding with a cleaning operation. Determine whether the part is cast iron, steel, aluminum or plastic. This can usually be distinguished by the inherent hardness and/or weight of the part.

2. If the part is iron or steel, use a scraper with a high carbon blade, for best results. The key is to use a high carbon steel blade that is "razor-sharp." With a sharp blade, very little effort is required to peel off the old gasket.

a. Lay the blade flat on the surface and push slowly and evenly. Don't allow the blade corners to tip in and mar the surface.

b. Rounding off the blade corners with a small grinder will prevent scratching and gouging of the gasket surface.

WARNING: USE EXTREME CARE TO KEEP HANDS AND FINGERS CLEAR OF THE BLADE.

3. If the part is aluminum or plastic, a different scraper must be used. Carbon steel or any other steel edge will cut, mar, gouge or burr aluminum and plastic. A teflon or hard wooden scraper is recommended. First use a commercially-available spray solvent, allowing ample time for the solvent to act on the gasket. A suitable solvent should evaporate and leave no residue behind. Otherwise, the residue can cause a new leak to form.

NOTE: UNDER NO CIRCUMSTANCES ARE ANY GASKET SURFACES TO BE CLEANED AND PREPARED FOR SEALING BY USING A HAND GRINDER, ROTARY WIRE BRUSH, SANDING DISC OR PAD OR ANY OTHER POWER TOOL USING AN ABRASIVE SURFACE AS A CUTTING TOOL. THESE TOOLS HAVE BEEN FOUND TO PROMOTE ENTRY OF SANDING GRIT AND GASKET MATERIAL INTO ENGINE CAVITIES. THESE TOOLS CAN DAMAGE THE SURFACE FINISH AND POSSIBLY DISTORT THE ORIGINAL FLATNESS OF THE COMPONENT, LEADING TO FURTHER VACUUM, COMPRESSION AND/OR FLUID LEAKS.

4. To prevent gasket material or other foreign matter from entering internal engine compartments, place CLEAN shop towels over exposed cavities. Use extreme care when removing the towels; remove them SLOWLY. Cloth towels can drop as much foreign material into the engine as they originally collected during cleaning operations.

5. Another alternative is to use a portable shop vacuum. Moving a vacuum nozzle closely along with the scraper edge will help direct loosened gasket particles into the vacuum and away from the engine.

6. The same care used in preparing the gasket surface should be practiced when assembling component parts such as the intake manifold and cylinder heads. Both are critical leak areas requiring extra care during assembly. Some things to consider are:

a. Not all engines use the same sealants in the same places. Some parts use no sealant at all.

b. Consult the service manual first. Don't assume that a gasket needs sealant. Some gaskets are designed with a pre-cast bead. Adding sealant to this design type will create a leak by shimming the two mating surfaces.

c. Although some aftermarket gaskets look the same as the ones removed, use only Ford original equipment parts to ensure that the customer receives consistent quality and value.

d. Avoid gasket locating products such as "tack'ems". These chemicals may leave residues in the engine that are incompatible with the oil, and may even cause damage to the catalytic converter.

7. Practice CLEANLINESS when reinstalling components and gaskets.

a. A small leak path can become a larger one as fluid erodes a gasket.

b. Keep dirt, lint and unwanted chemicals off new gaskets.

c. DO NOT assume that once dirt enters the engine that the oil filter will cleanse the oil to its original state and protect the engine from harmful abrasives. Particles such as silica (sand) are small enough to pass through even the best oil filters. The grinding effect of sand and dirt in oil on internal bearing or wear surfaces is comparable to the effect of valve compound for lapping-in valves.

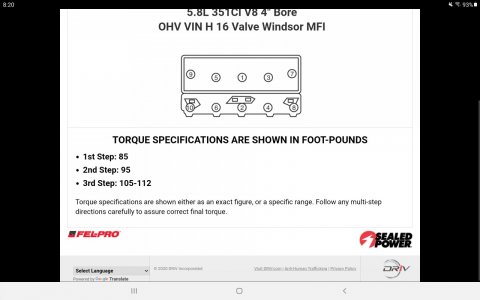

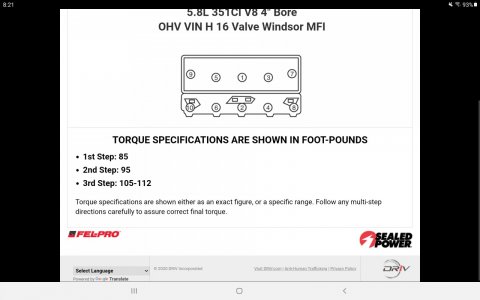

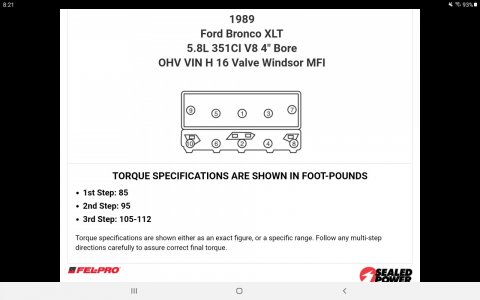

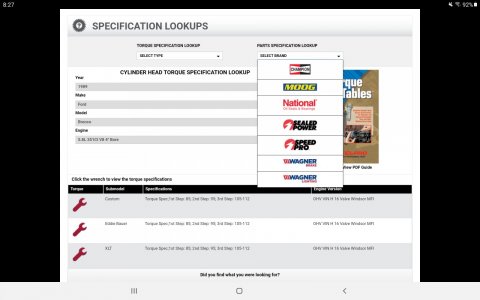

8. Torque sequence of components such as intake manifold and cylinder heads is extremely critical for proper sealing.

a. Not only does sequencing make a more effective seal, it also protects the part from warpage or distortions caused by improper tightening. b. Aluminum is particularly susceptible to warpage from uneven tightening of fasteners.

c. In some instances, fasteners used on aluminum components must be loosened in sequence. Consult the service Manual in EVERY instance for correct torque and/or de-torque values and sequences.

9. After a repair job, it is a good practice to use a black light leak test to confirm that the repair was successful. For example, it would be easy to assume that the rear main crankshaft seal was leaking when in fact the intake manifold gasket allowed oil to run down the back of the engine. Consider all the facts which allow fluid to travel outside the engine (fan air blast, road air blast, gravity, or escaping/pressurized fluid spray.

To sum-up, a successful leak repair depends on:

* Accurate diagnosis of the leak using Ford-recommended test equipment and procedures.

* Surface preparation and gasket installation using the proper cleaning tools.

* Exercising care and cleanliness during assembly/disassembly of components.

* Use of genuine Ford OEM parts.

OTHER APPLICABLE ARTICLES: 92-25-02

WARRANTY STATUS: INFORMATION ONLY" by Ford

Broken Bolt Removal Tip & Tool

Source: by Sixlitre (Malcolm H, Eddie Bauer) at SuperMotors.net