Hello Y'all,

I have a 1989 Ford Bronco 351 Windsor that my kid used as a mudder.

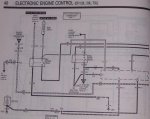

I replaced the negative battery cable and spliced original pigtail coupler on to new cable.

Trunk started afterwards but sometimes would not start after being driven. Now truck will not start and unplugging coupler changes behavior of starter.

Plugged in, starter runs but motor will not fire. Also the 2 wire get hot.

Un plugged and truck acts like battery is weak.

What is the purpose of the wires? Did I manage to wire in reverse order? What did I fry??

Thank you in advance for any information you can give me.

Not found on road dead, but Found On Rednecks Driveway.. Needs to move!!

I have a 1989 Ford Bronco 351 Windsor that my kid used as a mudder.

I replaced the negative battery cable and spliced original pigtail coupler on to new cable.

Trunk started afterwards but sometimes would not start after being driven. Now truck will not start and unplugging coupler changes behavior of starter.

Plugged in, starter runs but motor will not fire. Also the 2 wire get hot.

Un plugged and truck acts like battery is weak.

What is the purpose of the wires? Did I manage to wire in reverse order? What did I fry??

Thank you in advance for any information you can give me.

Not found on road dead, but Found On Rednecks Driveway.. Needs to move!!

Last edited by a moderator: