Yo

The code does lead Primarily to a vacuum leak in the Secondary Air Injection; Pump (Smog Pump), Thermactor Air Bypass (TAB) & Thermactor Air Diverter (TAD) Solenoids; Diverter, Check & Bypass Valves, Cross-Over Tube, etc.

The 2ndry air system is known to fail in a wide variety of ways. The check valves that prevent hot exhaust from entering the rubber hoses age, rust, leak, & crack open melting the plastic TAB & TAD valves, creating exhaust leaks that can damage other components, raising exhaust oxygen levels (setting lean codes or rich adaptive limit codes), and making rattling noises. The hard steel tubing between the exhaust & the check valve can rust or crack (especially the infamous "crossover tube" on the backs of V8 heads). The vacuum controls leak (including the "coffee can" reservoir on the R wheelwell), get misrouted during other repairs, or the diaphragms rupture. The electronics that control the vacuum controls can fail electrically or mechanically, or the wires can be damaged. But all of these failures are either A) relatively cheap & easy to repair, or B) cheap & easy to prevent with normal inspection & maintenance.

The early steel coffee can reservoir commonly rusts &/or cracks, and the later plastic reservoir is an easy upgrade

Thermactor System (Smog/ Air Pump) Operational Description; "...This pumps fresh air into the exhaust system, to burn left over hydrocarbons, lowering emissions. The computer uses 2 air valves (TAB & TAD) to control where the air flows depending on engine operation. Thermactor Air Bypass (TAB) shunts air to the atmosphere, when no air is needed. When air is needed it sends air to the second valve TAD. Thermactor Air Diverter (TAD) diverts air either to the exhaust manifold, or directly to catalytic converter..." MIESK5 NOTE; If da Engine Coolant Temperature Sensor (ECT) is Below 50 degrees F, then TAB is grounded & sends air to atmosphere; If Between 50 and 190 Degrees F, Bypass Valve sends air to Diverter and to Manifold; If Over 190 Degrees F, it is in closed loop & Air goes to Catalytic Converter; Bypass when at idle/Wide Open Throttle (WOT), and with failing Oxygen Sensor. The fastest way to see if vehicle is in open loop is to see where the air is going; to Catalytic Converter, it is in Closed Loop; to Atmosphere or Manifold it is in Closed Loop, provided the thermactor system is working; miesk5 Note, Air for the Thermactor system is cleaned by means of a centrifugal filter fan mounted on the air pump driveshaft. The air filter does not require any type of replaceable element. To prevent excessive pressure, the air pump is equipped with a pressure relief valve which uses a replaceable plastic plug to control the pressure setting. The Thermactor air pump has sealed bearings which are lubricated for the life of the unit and preset rotor vane and bearing clearances, which do not require any periodic adjustments. The air supply from the pump is controlled by the air by-pass valve, sometimes called a dump valve. During engine deceleration, the air by-pass valve opens, momentarily diverting the air supply through a silencer and into the atmosphere, thus preventing backfires within the exhaust system when deceleration supplies larger-than-normal amounts of unburned fuel to the exhaust ports. check valve is incorporated in the air inlet side of the air manifolds. Its purpose is to prevent exhaust gases from backing up into the Thermactor system. This valve is especially important in the event of drive belt failure and also during deceleration, when the air by-pass valve is dumping the air supply. The air manifolds and air supply tubes channel the air from the Thermactor air pump into the exhaust ports of each cylinder, thus completing the cycle of the Thermactor system. Beginning in 1968, a conspicuous decal listing all tune-up specifications which contribute to the effectiveness of the emission control equipment is located in the engine compartment..."

Source: by Ryan M

♤

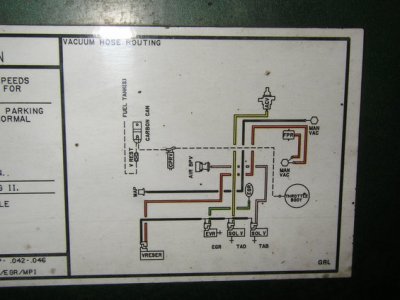

Thermactor Air Bypass Valve Location pic in a 90 5.8; "...The Pink Vacuum Line goes from the TAB Solenoid (driver's side rear solenoid) to the passenger side (adjacent to the Vacuum Reservoir Can) and down to the bottom of the TAB (Bypass) Valve. Note that my Pink Vacuum line appears Yellowish in this pic and is not yet connected to the base of the TAB Valve as I was working up a solution at the time..."

Source: by Seattle FSB (SeattleFSB)

Crossover Tube, Diverter & Check Valves & Hoses Location pic in a V 8

http://www.supermotors.net/getfile/317749/fullsize/xtubenew.jpg

http://www.supermotors.net/registry/media/252396

http://www.supermotors.net/registry/media/227282

http://www.supermotors.net/registry/media/252396

http://www.supermotors.net/registry/media/227282

I couldn't post these pics in a PM reply due to error messages about some BS concerning something not explained. Such as "This image is not allowed".