So I may buy a new 96 Bronco and it has issues. One of the issues that may make me buy it or not is that the ABS light is on.

If its a wheel sensor no problem, if its the ABS hydraulic computer, forget it. After what I went through with a Jeep I had forget it. Half of the used ones never work. I ended up buying an entrire car to get one that worked, not doing that again

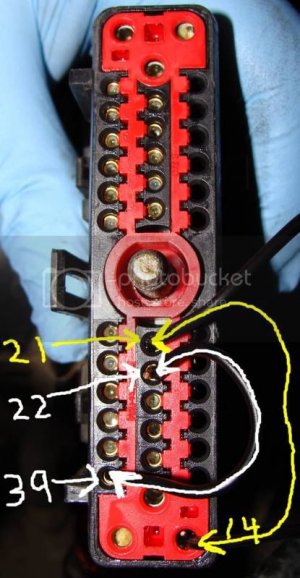

Anyways, I had the idea of connecting an OBDII code reader and have it tell me. Prev owner says you can not do that and you need to connect to some different connector or harness, etc

Any ideas on how I can easily tell if its the module vs a wheel sensor?

If its a wheel sensor no problem, if its the ABS hydraulic computer, forget it. After what I went through with a Jeep I had forget it. Half of the used ones never work. I ended up buying an entrire car to get one that worked, not doing that again

Anyways, I had the idea of connecting an OBDII code reader and have it tell me. Prev owner says you can not do that and you need to connect to some different connector or harness, etc

Any ideas on how I can easily tell if its the module vs a wheel sensor?