Yo Ymehawa11,

Welcome!

Did the symptoms occur before you replaced those parts or after?

code

Contaminated Oxygen Sensor pics w/Diagnosis, General

Source: by Tomco

Contamination will make the sensor function inaccurately, which will lead to poor performance, poor fuel economy and high emissions. @

http://redirect.viglink.com/?format=go&jsonp=vglnk_147974637430615&key=6ed47b392b9edfe394b9e89b72717104&libId=ivsaovt601000bgv000MA7ipqx9k2&loc=http%3A%2F%2Fwww.fullsizebronco.com%2Fforum%2F7-1980-96-bronco-tech%2F155932-302-iac-signal-2.html&v=1&out=http%3A%2F%2Fcds.activant.com%2FC2C%2FC01%2F68%2F541%2F824663110.pdf&ref=http%3A%2F%2Fwww.fullsizebronco.com%2Fforum%2F6135985-post5.html&title=302%20IAC%20Signal%3F%3F%20-%20Page%202%20-%20Ford%20Bronco%20Forum&txt=Contaminated%20Oxygen%20Sensor%20pics%20w%2FDiagnosis%2C%20General%20%0ASource%3A%20by%20Tomco%0AContamination%20will%20make%20the%20sensor%20function%20inaccurate...

DTC 41, 42, 91, 92, 136, 137,139, 144, 171, 172, 173, 175, 176, 177 & some Possible Causes for Rich & Lean HEGO The engine temperature must be greater than 50°F (10°C) to pass the KOEO Self-Test and greater than 180°F (82°C) to pass the KOER Self-Test. To accomplish this, the engine should be at normal operating temperature

Source: by Ryan M (Fireguy50)

DTC 41, 42, 85 OR THREE DIGIT CODES 171, 172, 173, 179, 181, 182, 183 & 565 are received , Check for proper HEGO Ground; in Catalytic Converter Diagnosis TSB 91-12-11 for 86-91 Bronco, F Series, & Econoline

Source: by Ford

Publication Date: JUNE 12, 1991

TRUCK: 1986-91 BRONCO, ECONOLINE, F-150-350 SERIES

1988-91 F SUPER DUTY, F47

ISSUE: Lack of power or a no start condition may be diagnosed as an exhaust restriction caused by a plugged catalytic converter. A plugged catalytic converter (internal deterioration) is usually caused by abnormal engine operation.

ACTION: Diagnose the catalytic converter to confirm internal failure. Refer to the Catalyst and Exhaust System Diagnostic Section, in the Engine/Emissions Diagnostic Shop Manual and the following procedures for service details.

SERVICE PROCEDURE

1. Lack of proper HEGO operation may cause, or be the result of a rich or lean fuel condition, which could cause additional heat in the catalyst. Perform self test KOEO and KOER, service any codes.

NOTE: IF TWO DIGIT CODES 41, 42, 85 OR THREE DIGIT CODES 171, 172, 173, 179, 181, 182, 183 AND 565 ARE RECIEVED, CHECK FOR PROPER HEGO GROUND.

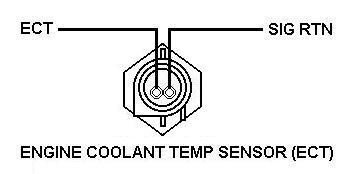

Here is the wiring diagram for the HEGO.

It shows that the heater circuit is not used on 5.0 engines.

http://www.revbase.com/BBBMotor/Wd/DownloadPdf?id=21138

Just in case check that G802 Shown in diagram is good on RH inner fender behind headlights;

If the HEGO ground is good, the following areas may be at fault:

* Ignition Coil

* Distributor Cap

* Distributor Rotor

* Fouled Spark Plug

* Spark Plug Wires

* Air Filter

* Stuck Open Injector

* Fuel Contamination with Engine OIL

* Manifold Leaks Intake/Exhaust

* Fuel Pressure

* Poor Power Ground

* Engine Not At Normal Operating Temperature

* HEGO Sensor

2. Spark timing that is ******** from specification may increase exhaust gas temperature and shorten catalyst life. Refer to the following procedure for service details.

a. Check spark timing. Check base timing with spout disconnected. Set base timing to the specification on the vehicle emission decal.

b. Check computed timing. How to Set the timing on an EFI Ford spout connected. by Ryan M. @

http://www.fuelinjectedford.com/page71.html

NOTE: COMPUTED TIMING IS EQUAL TO BASE TIMING PLUS 20° BTDC ± 3°.

3. Misfiring spark plugs may cause an unburned fuel air mixture to pass through the catalyst, which could cause higher than normal catalyst temperatures. Refer to the following procedure for service details. Check secondary ignition, hook the vehicle up to an engine analyzer and check for a secondary ignition misfire.

Spark Plug Diagnosis @

http://www.aa1car.com/library/reading_spark_plugs.jpg

NOTE: SERVICE ANY ITEM THAT IS NOT PERFORMING AT PROPER SPECIFICATIONS BEFORE CONTINUING.

4. Fuel pressure that is too high may cause rich air fuel mixtures to pass through the catalyst which could cause higher than normal catalyst temperatures. Refer to the following procedure for service details.

a. Check fuel pressure, install fuel pressure gauge, start and run the engine at idle. Fuel pressures between 28 and 34 PSI are typical (4.9L typically is 15 PSI higher).

b. Disconnect the vacuum line going to the fuel pressure regulator. Fuel pressure typically jumps to 40 PSI ± 3 PSI (4.9L typically is 15 PSI higher). Visually inspect vacuum line for raw fuel.

NOTE: FUEL PRESSURES ABOVE THESE VALUES SHOULD BE CORRECTED. HOWEVER, THIS MAY NOT BE THE CAUSE OF THE CONCERN. SERVICE AS NECESSARY.

5. Throttle plates in the throttle body not returning to the proper closed position may cause excessive catalyst temperatures during downhill grades. Refer to the following procedure for service details. Visually inspect the throttle body and linkage for:

* Binding or sticking throttle linkage.

* Tight speed control linkage or cable.

* Vacuum line interference.

* Electrical harness interference.

NOTE: AFTERMARKET GOVERNORS, THROTTLE LINKAGE AND CABLES ASSOCIATED WITH POWER TAKE-OFF UNITS, MAY ALSO INTERFERE WITH PROPER THROTTLE RETURN. SERVICE AS NECESSARY.

6. It is extremely important that all systems related to the engine and emission systems operate properly.

a. Visually inspect the engine compartment to make sure all vacuum hoses and spark plug wires are properly routed and securely connected.

b. Inspect all wiring harnesses and connectors for insulation damage, burned, overheated, loose or broken conditions.

c. Verify proper operation of the thermactor system. Thermactor systems that fail to dump thermactor air to the atmosphere properly or at the correct time can cause high catalyst temperatures.

d. Visually inspect thermactor system for damaged or kinked hoses and perform a function test on following components: air control valve, check valve, silencer, filter and the air bypass solenoid.

e. Verify proper operation of the engine cooling system thermostat.

...

See my Vacuum leak diagnosis in post #20 @

http://broncozone.com/topic/23994-90-58l-getting-continuous-code-33-and-running-code-44/?p=125535

There is a way to test for fuel volume, but it is dangerous.

Is it a C6 transmission?