Hi, I've got two questions.

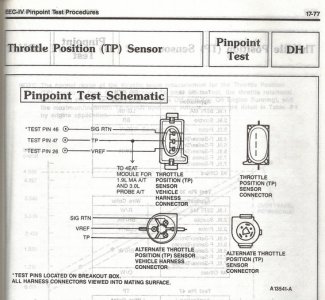

I just finished rebuilding the engine for a friend's 1996 Bronco. It's a 351w. First question is about the 121 code that I can't rid of: "Closed throttle voltage higher or lower than expected." The voltage between green and black wires on the throttle position sensor (TPS) is ~.54 volts. Other postings say it's supposed to be somewhere between .6 and .9 v, preferably closer to .9 v. Some postings say to loosen the screws and move the sensor around to vary the voltage. First, it seems to be impossible to loosen the screws while the throttle body is attached to manifold so real time adjustment would appear challenging. Secondly, even with the screws loosened, there is very little play in the positioning. So I purchased a new TPS and replaced the old one. I get the same error code with the new one. Could I be installing it backwards? Which way do the wires go? Toward the IAC side or toward the outside of engine, like where the EGR valve is? I have the wires toward the outside. Note that I did try the old one with the wires toward the IAC and I still got the error and low measured voltage.

Second question. I have timed the engine at 10 degrees BTC with the spout on. Seems to work OK. However, all postings say to remove the spout and then do the timing. Every time I remove the spout from the distributor, the engine dies immediately. What's going here? Is this expected behavior?

Would appreciate any help. Engine actually runs really well and I'm pleased with my rebuild. Just seeing if there is upside to be had.

Rebuild pictures if interested:

https://picasaweb.google.com/106068607007984139595/Bronco

I just finished rebuilding the engine for a friend's 1996 Bronco. It's a 351w. First question is about the 121 code that I can't rid of: "Closed throttle voltage higher or lower than expected." The voltage between green and black wires on the throttle position sensor (TPS) is ~.54 volts. Other postings say it's supposed to be somewhere between .6 and .9 v, preferably closer to .9 v. Some postings say to loosen the screws and move the sensor around to vary the voltage. First, it seems to be impossible to loosen the screws while the throttle body is attached to manifold so real time adjustment would appear challenging. Secondly, even with the screws loosened, there is very little play in the positioning. So I purchased a new TPS and replaced the old one. I get the same error code with the new one. Could I be installing it backwards? Which way do the wires go? Toward the IAC side or toward the outside of engine, like where the EGR valve is? I have the wires toward the outside. Note that I did try the old one with the wires toward the IAC and I still got the error and low measured voltage.

Second question. I have timed the engine at 10 degrees BTC with the spout on. Seems to work OK. However, all postings say to remove the spout and then do the timing. Every time I remove the spout from the distributor, the engine dies immediately. What's going here? Is this expected behavior?

Would appreciate any help. Engine actually runs really well and I'm pleased with my rebuild. Just seeing if there is upside to be had.

Rebuild pictures if interested:

https://picasaweb.google.com/106068607007984139595/Bronco